Page 173 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 173

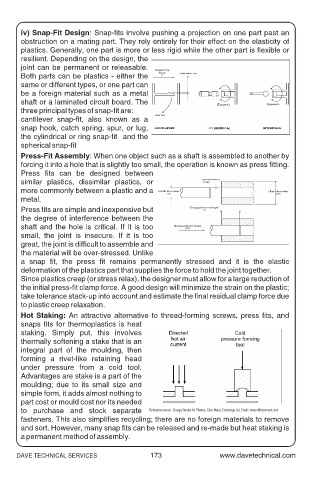

iv) Snap-Fit Design: Snap-fits involve pushing a projection on one part past an

obstruction on a mating part. They rely entirely for their effect on the elasticity of

plastics. Generally, one part is more or less rigid while the other part is flexible or

resilient. Depending on the design, the

joint can be permanent or releasable.

Both parts can be plastics - either the

same or different types, or one part can

be a foreign material such as a metal

shaft or a laminated circuit board. The

three principal types of snap-fit are:

cantilever snap-fit, also known as a

snap hook, catch spring, spur, or lug,

the cylindrical or ring snap-fit and the

spherical snap-fit

Press-Fit Assembly: When one object such as a shaft is assembled to another by

forcing it into a hole that is slightly too small, the operation is known as press fitting.

Press fits can be designed between

similar plastics, dissimilar plastics, or

more commonly between a plastic and a

metal.

Press fits are simple and inexpensive but

the degree of interference between the

shaft and the hole is critical. If it is too

small, the joint is insecure. If it is too

great, the joint is difficult to assemble and

the material will be over-stressed. Unlike

a snap fit, the press fit remains permanently stressed and it is the elastic

deformation of the plastics part that supplies the force to hold the joint together.

Since plastics creep (or stress relax), the designer must allow for a large reduction of

the initial press-fit clamp force. A good design will minimize the strain on the plastic;

take tolerance stack-up into account and estimate the final residual clamp force due

to plastic creep relaxation.

Hot Staking: An attractive alternative to thread-forming screws, press fits, and

snaps fits for thermoplastics is heat

staking. Simply put, this involves

thermally softening a stake that is an

integral part of the moulding, then

forming a rivet-like retaining head

under pressure from a cold tool.

Advantages are stake is a part of the

moulding; due to its small size and

simple form, it adds almost nothing to

part cost or mould cost nor its needed

to purchase and stock separate Referance source - Design Guides for Plastics, Clive Maier, Econology Ltd, Email: cmaier@btconnect.com

fasteners. This also simplifies recycling; there are no foreign materials to remove

and sort. However, many snap fits can be released and re-made but heat staking is

a permanent method of assembly.

DAVE TECHNICAL SERVICES 173