Page 85 - Hot Runner & Control Systems 2020

P. 85

Straight-Shot Hot Sprue Bushings 83

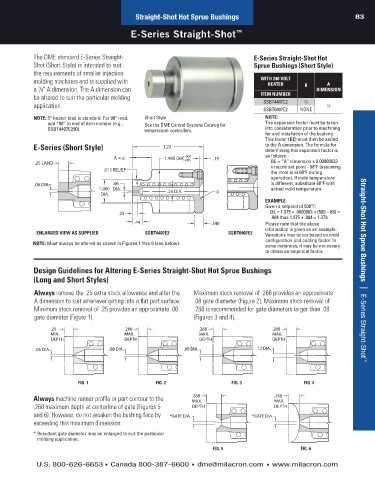

E-Series Straight-Shot ™

The DME standard E-Series Straight- E-Series Straight-Shot Hot

Shot (Short Style) is intended to suit Sprue Bushings (Short Style)

the requirements of smaller injection

molding machines and is supplied with WITH 240 VOLT R A

HEATER

a /8" A dimension. The A dimension can DIMENSION

7

be altered to suit the particular molding ITEM NUMBER 1

application. SSBT4407E2 ⁄2 7 ⁄8

SSBT0407E2 NONE

NOTE: 5° heater lead is standard. For 90° lead, Short Style NOTE:

add “90” to end of item number (e.g., See the DME Control Systems Catalog for The expansion factor must be taken

SSBT4407E290). temperature controllers. into consideration prior to machining

for and installation of the bushing.

This factor (BE) must then be added

E-Series (Short Style) 3.22 to the A dimension. The formula for

determining this expansion factor is

7 +.000 as follows:

A = 8 1.995 DIA. –.005 .19

.25 LAND BE = “A” dimension x 0.00000633

.015 RELIEF x nozzle set point - 68ºF (assuming

the mold is at 68ºF during

operation). If mold temperature

.06 DIA. .06 is different, substitute 68ºF with

1.000 DIA. .25 DIA. actual mold temperature.

DIA. R

EXAMPLE:

Given a setpoint of 500°F:

.25 BE = 1.375 × .0000063 × (500 – 68) =

.004 thus 1.375 + .004 = 1.379.

.44 .340 Please note that the above

information is given as an example.

ENLARGED VIEW AS SUPPLIED SSBT4407E2 SSBT0407E2 Variations may occur based on mold

configuration and cooling factor. In

NOTE: Must always be altered as shown in Figures 1 thru 6 (see below). some instances, it may be necessary

to obtain an empirical factor.

Design Guidelines for Altering E-Series Straight-Shot Hot Sprue Bushings Hot Runner Systems | 4-Zone and 8-Zone Timer-Based Sequencers

(Long and Short Styles)

Always remove the .25 extra stock allowance and alter the Maximum stock removal of .268 provides an approximate

A dimension to suit whenever gating into a flat part surface. .08 gate diameter (Figure 2). Maximum stock removal of

Minimum stock removal of .25 provides an approximate .06 .268 is recommended for gate diameters larger than .08

gate diameter (Figure 1). (Figures 3 and 4).

.25 .268 .268 .268

MIN. MAX. MAX. MAX.

DEPTH DEPTH DEPTH DEPTH

.06 DIA. .08 DIA. .09 DIA. .12 DIA.

Straight-Shot Hot Sprue Bushings | E-Series Straight-Shot ™

FIG. 1 FIG. 2 FIG. 3 FIG. 4

Always machine runner profile or part contour to the .268 .268

MAX.

MAX.

.268 maximum depth at centerline of gate (Figures 5 DEPTH DEPTH

and 6). However, do not weaken the bushing face by *GATE DIA. *GATE DIA.

exceeding this maximum dimension.

* Resultant gate diameter may be enlarged to suit the particular

molding application.

FIG. 5 FIG. 6

U.S. 800-626-6653 n Canada 800-387-6600 n dme@milacron.com n www.milacron.com