Page 86 - Hot Runner & Control Systems 2020

P. 86

84 Straight-Shot Hot Sprue Bushings

ER-Series Straight-Shot ™

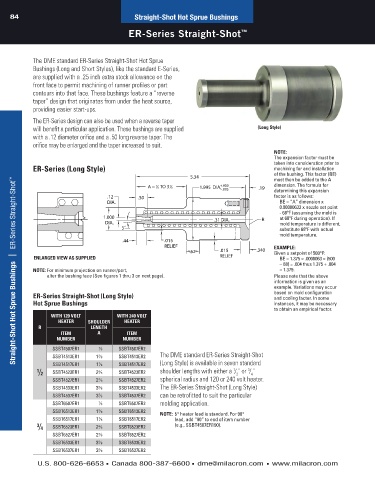

The DME standard ER-Series Straight-Shot Hot Sprue

Bushings (Long and Short Styles), like the standard E-Series,

are supplied with a .25 inch extra stock allowance on the

front face to permit machining of runner profiles or part

contours into that face. These bushings feature a “reverse

taper” design that originates from under the heat source,

providing easier start-ups.

The ER-Series design can also be used when a reverse taper

will benefit a particular application. These bushings are supplied (Long Style)

with a .12 diameter orifice and a .50 long reverse taper. The

orifice may be enlarged and the taper i ncreased to suit.

NOTE:

The expansion factor must be

taken into consideration prior to

ER-Series (Long Style) machining for and installation

Hot Runner Systems | 4-Zone and 8-Zone Timer-Based Sequencers

5.34 of the bushing. This factor (BE)

Straight-Shot Hot Sprue Bushings | ER-Series Straight-Shot ™

must then be added to the A

A = 8 TO 3 7 8 1.995 DIA. +.000 .19 dimension. The formula for

7

–.005

determining this expansion

.12 .50 factor is as follows:

DIA. BE = “A” dimension x

0.00000633 x nozzle set point

- 68ºF (assuming the mold is

1.000 .31 DIA. R at 68ºF during operation). If

DIA. mold temperature is different,

5˚ substitute 68ºF with actual

mold temperature.

.44 .015

RELIEF EXAMPLE:

.62 .015 .340 Given a setpoint of 500°F:

ENLARGED VIEW AS SUPPLIED RELIEF BE = 1.375 × .0000063 × (500

– 68) = .004 thus 1.375 + .004

NOTE: For minimum projection on runner/part, = 1.379.

alter the bushing face (See figures 1 thru 3 on next page). Please note that the above

information is given as an

example. Variations may occur

ER-Series Straight-Shot (Long Style) based on mold configuration

and cooling factor. In some

Hot Sprue Bushings instances, it may be necessary

to obtain an empirical factor.

WITH 120 VOLT WITH 240 VOLT

HEATER SHOULDER HEATER

R LENGTH

ITEM A ITEM

NUMBER NUMBER

SSBT4507ER1 7 ⁄8 SSBT4507ER2

SSBT4513ER1 1 ⁄8 SSBT4513ER2 The DME standard ER-Series Straight-Shot

3

SSBT4517ER1 1 ⁄8 SSBT4517ER2 (Long Style) is available in seven standard

7

1 3 shoulder lengths with either a / " or / "

3

1

⁄2 SSBT4523ER1 2 ⁄8 SSBT4523ER2 2 4

SSBT4527ER1 2 ⁄8 SSBT4527ER2 spherical radius and 120 or 240 volt heater.

7

SSBT4533ER1 3 ⁄8 SSBT4533ER2 The ER-Series Straight-Shot (Long Style)

3

SSBT4537ER1 3 ⁄8 SSBT4537ER2 can be retrofitted to suit the particular

7

SSBT6507ER1 7 ⁄8 SSBT6507ER2 molding application.

SSBT6513ER1 1 ⁄8 SSBT6513ER2 NOTE: 5° heater lead is standard. For 90°

3

SSBT6517ER1 1 ⁄8 SSBT6517ER2 lead, add “90” to end of item number

7

3 ⁄4 SSBT6523ER1 2 ⁄8 SSBT6523ER2 (e.g., SSBT4507ER190).

3

SSBT6527ER1 2 ⁄8 SSBT6527ER2

7

SSBT6533ER1 3 ⁄8 SSBT6533ER2

3

SSBT6537ER1 3 ⁄8 SSBT6537ER2

7

U.S. 800-626-6653 n Canada 800-387-6600 n dme@milacron.com n www.milacron.com