Page 38 - CFCM Nov-Dec-2020 Final_Neat

P. 38

plating and anodizing: PUMPS AND FILTERS

Maintaining Flow

Choosing Pumps and Filters

THE DIVERSE PROCESSES of plating and anodizing require

equally diverse pumps.

Pumps are used to provide flow through eductors for

mixing in plating tanks without introducing air, provide

flow through filters to keep plating solutions clean, empty

and refill tanks with plating solutions, transfer chemicals

and rinse waters from sumps, and transfer wastewater and

water treatment chemicals in on-site treatment plants.

Filter Pump Industries manufactures pumps for every

industrial application. Its Penguin pumps are rugged, com-

pact, energy-efficient, corrosion-resistant, capable of han-

dling both high temperatures and high flow rates, and fea-

ture the latest hydraulic technology, the company says.

The vertical pump line features an extended design for im-

mersion into solutions.

Filter Pump Industries’ PSS Stainless Steel Vertical In-Tank

Pump is described as compact and simple, with only one

moving part. These pumps are suited to cleaners, caustics,

salt solutions, chlorinated solvents, photographic chemicals,

deionized water, fatty, phosphoric, citric, or lactic acids. Max-

imum temperature ratings are primarily dependent on the

elastomer employed and the vapor pressure of the liquid

being pumped, Filter Pump Industries says.

A replaceable coupled shaft using multiple set screws

to minimize shaft deflection and misalignment also allows

the use of standard NEMA motors, available at most motor

suppliers, saving prolonged downtime and money. A motor

stand-off and polytetrafluoroethylene (PTFE) slinger/disk

provide optimum bottom motor bearing protection against

chemical fume corrosiveness. Single-phase motors are wired

for 115 volts using a six-foot cord and grounding plug or

for 230 volts using a six-foot cord without plug. All three-

phase motors are shipped unwired, so that the direction of

motor rotation must be determined by the end user prior

to operation.

The PSS is recommended for OEMs, chemical wet pro-

cessing, spray rinse pumping, wet processing, standby

pumping, recirculating pumping, fume scrubbing, water

treatment, plating and etching, and more.

Filter Pump Industries offers six different types of filters

from cotton and polypropylene string wound to special-

ized polyurethane resin for various applications such as

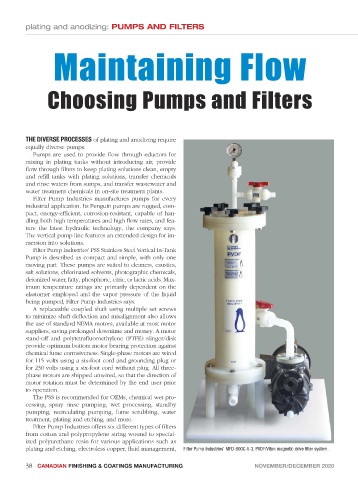

plating and etching, electroless copper, fluid management, Filter Pump Industries’ MFD-600C-V-3, PVDF/Viton magnetic drive filter system.

38 CAnADIAn FInISHInG & COATInGS MAnuFACTuRInG nOvEMbER/DECEMbER 2020