Page 374 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 374

Hose Hose Assembly and Crimping (cont.)

A Field Attachable

Series 51, BU & MS (Do not use these fittings on oxygen service lines)

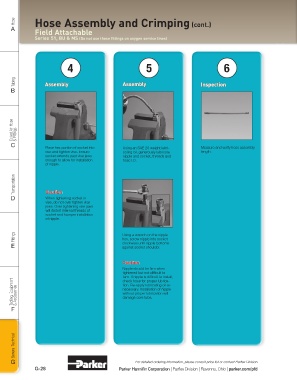

4 5 6

Tubing Assembly Assembly Inspection

B

Coiled Air Hose & Fittings

C Place hex portion of socket into Using an SAE 20 weight lubri- Measure and verify hose assembly

vise and tighten vise. Ensure cating oil, generously lubricate length.

socket extends past vise jaws nipple and socket, threads and

enough to allow for installation hose I.D.

of nipple.

Transportation

D Caution

When tightening socket in

vise, do not over tighten vise

jaws. Over tightening vise jaws

will distort internal threads of

socket and hamper installation

of nipple.

Fittings Using a wrench on the nipple

hex, screw nipple into socket

E clockwise until nipple bottoms

against socket shoulder.

Caution

Nipple should be firm when

tightened but not difficult to

turn. If nipple is difficult to install,

Tooling, Equipment & Accessories tion. Re-apply lubricating oil as

check hose for proper lubrica-

necessary. Installation of nipple

without proper lubrication will

damage core tube.

F

General Technical

G For detailed ordering information, please consult price list or contact Parflex Division.

G-28 Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd