Page 373 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 373

Hose Assembly and Crimping CAUTION: There are several different sections for Hose

Field Attachable Hose Assembly and Crimping. Be sure you are in A

the section that corresponds to the fitting series

Series 51, BU & MS (Do not use these fittings on oxygen service lines) you are using. See Table of Contents for listing.

1 2 3

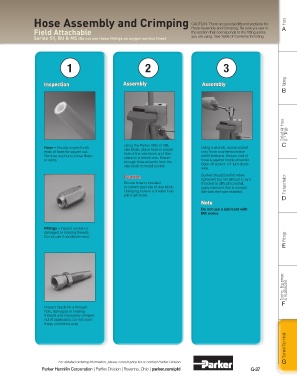

Inspection Assembly Assembly Tubing

B

Coiled Air Hose & Fittings

Using the Parker VBS or VBL

Hose – Visually inspect both Lubrication – Using an SAE Using a wrench, screw socket C

vise block, place hose in proper

ends of hose for square cut. 20 weight lubricating oil, lightly onto hose counterclockwise

hole of the vise block and then

lubricate inside of hose end.

Remove any burrs, loose fibers Lubricate – Using an SAE 20 until it bottoms. Ensure end of

clamp in a bench vise. Ensure

or wires. weight lubricating oil, hose is against inside shoulder.

enough hose extends from the

lightly lubricate inside and Back off socket 1/4 turn clock-

vise block to install socket.

outside of hose end. wise.

Caution Socket should be firm when

tightened but not difficult to turn.

Ensure hose is installed If socket is difficult to install, Transportation

in correct size hole of vise block. apply lubricant that is compat-

Clamping hose in a smaller hole ible with the hose material.

will crush hose.

D

Note

Do not use a lubricant with

MS series.

Fittings – Inspect socket for

damaged or missing threads. Using a Parker VBS or VBL

Do not use if conditions exist. (vise block), place hose in Fittings

proper hole of vise block and

place in bench vise. Ensure E

enough hose extends from

vise block to install socket.

Tooling, Equipment & Accessories

F

Inspect nipple for a through-

hole, damaged or missing

threads and improperly crimped

nut (if applicable). Do not use if

these conditions exist.

General Technical

For detailed ordering information, please consult price list or contact Parflex Division. G

Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd G-27