Page 378 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 378

Hose Hose Assembly and Crimping

A PTFE Permanent Crimp CAUTION: There are several different sections for Hose Assembly

Series PAGE Fittings and Crimping. Be sure you are in the section that corresponds to the

fitting series you are using. See Table of Contents for listing.

1 2 3

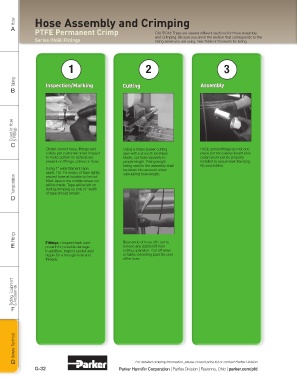

Tubing Inspection/Marking Cutting Assembly

B

Coiled Air Hose & Fittings

C

Obtain correct hose, fittings and Using a rotary power cutting PAGE series fittings are not one

collars per customer order. Inspect saw with a smooth toothless piece but two pieces (insert plus

to make certain no defects are blade, cut hose squarely to collar) and must be properly

present on fittings, collars or hose. proper length. Fitting length installed to assure leak free long

being used in the assembly shall life assemblies.

Using 1" wide filament tape, be taken into account when

apply 1 to 1½ wraps of tape tightly calculating hose length.

around hose at location to be cut.

Transportation Mark tape in the middle where cut

will be made. Tape will be left on

during crimping so only ½" width

D of tape should remain.

Fittings

E Fittings – Inspect each com- Blow ends of hose off / out to

remove any debris left from

ponent for possible damage.

In addition, inspect socket and cutting operation. Cut off wires

nipple for a through-hole and or fabric extending past the end

threads. ofthe hose.

Tooling, Equipment & Accessories

F

General Technical

G For detailed ordering information, please consult price list or contact Parflex Division.

G-32 Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd