Page 383 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 383

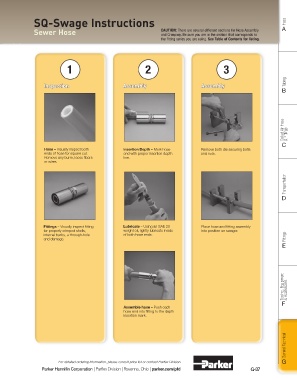

SQ-Swage Instructions Hose

Sewer Hose CAUTION: There are several different sections for Hose Assembly A

and Crimping. Be sure you are in the section that corresponds to

the fitting series you are using. See Table of Contents for listing.

1 2 3

Tubing

Measure & Inspect Inspection Assembly Assembly

B

Coiled Air Hose & Fittings

C

Hose – Visually inspect both Insertion Depth – Mark hose Remove both die securing bolts

ends of hose for square cut. end with proper insertion depth and nuts.

Remove any burrs, loose fibers line.

or wires.

Transportation

D

Fittings – Visually inspect fitting Lubricate – Using an SAE 20 Place hose and fitting assembly

for properly crimped shells, weight oil, lightly lubricate inside into position on swager.

internal barbs, a through-hole of both hose ends. Fittings

and damage.

E

Tooling, Equipment & Accessories

F

Assemble hose – Push each

hose end into fitting to the depth

insertion mark.

General Technical

For detailed ordering information, please consult price list or contact Parflex Division. G

Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd G-37