Page 11 - Eaton - Gas/Liquid separators

P. 11

Gas/Liquid Separation Fabricated Construction

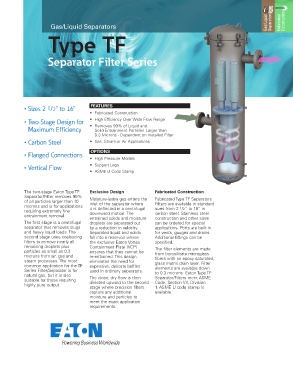

Gas/Liquid Separators

Type TF

Separator Filter Series

• Sizes 2 /2” to 16” FEATURES

1

• Fabricated Construction

• Two-Stage Design for • High Efficiency Over Wide Flow Range

Maximum Efficiency • Removes 99% of Liquid and

Solid Entrainment Particles Larger than

0.3 Microns - Dependent on Installed Filter

• Carbon Steel • Gas, Steam or Air Applications

• Flanged Connections OPTIONS

• High Pressure Models

• Vertical Flow • Support Legs

• ASME U Code Stamp

The two-stage Eaton Type TF Exclusive Design Fabricated Construction

Separator/Filter removes 99% Moisture-laden gas enters the Fabricated Type TF Separators

of all particles larger than 10 inlet of the separator where Filters are available in standard

microns and is for applications it is deflected in a centrifugal sizes from 2 1 /2” to 16” in

requiring extremely fine downward motion. The carbon steel. Stainless steel

entrainment removal. entrained solids and moisture construction and other sizes

The first stage is a centrifugal droplets are separated out can be ordered for special

separator that removes slugs by a reduction in velocity. applications. Ports are built in

and heavy liquid loads. The Separated liquid and solids for vents, gauges and drains.

second stage uses coalescing fall into a reservoir where Additional fittings can be

filters to remove nearly all the exclusive Eaton Vortex specified.

remaining droplets plus Containment Plate (VCP) The filter elements are made

particles as small as 0.3 ensures that they cannot be from borosilicate microglass

microns from air, gas and re-entrained. This design fibers with an epoxy saturated,

steam processes. The most eliminates the need for glass matrix drain layer. Filter

common application for the TF expensive, delicate baffles elements are available down

Series Filter/Separator is for used in ordinary separators. to 0.3 microns. Eaton Type TF

natural gas, but it is also The clean, dry flow is then Separator/Filters meet ASME

suitable for those requiring directed upward to the second Code, Section VII, Division

highly pure output.

stage where precision filters 1. ASME U code stamp is

capture any additional available.

moisture and particles to

meet the exact application

requirements.