Page 294 - Wago_ThePluggableConnectionSystem_Volume5_2015_US.pdf

P. 294

®

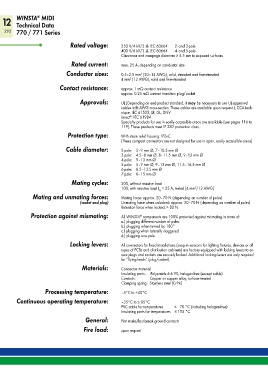

12 WINSTA MIDI

Technical Data

292 770 / 771 Series

Rated voltage: 250 V/4 kV/3 â IEC 60664 2- and 3-pole

400 V/6 kV/3 â IEC 60664 4- and 5-pole

Clearance and creepage distances ≥ 5.5 mm to exposed surfaces

Rated current: max. 25 A, depending on conductor size

Conductor sizes: 0.5–2.5 mm (20–14 AWG), solid, stranded and fine-stranded

2

4 mm (12 AWG), solid and fine-stranded

2

Contact resistance: approx. 1 mΩ contact resistance

approx. 0.25 mΩ contact transition plug/socket

Approvals: UL (Depending on end-product standard, it may be necessary to use UL-approved

cables with AWG cross-section. These cables are available upon request.), CCA tech-

nique, IEC 61535, LR, GL, DNV

Linect : IEC 61984

®

Specialty products for use in easily accessible areas are available (see pages 116 to

119). These products meet IP 2XD protection class.

Protection type: With strain relief housing: IP2xC

(These compact connectors are not designed for use in open, easily accessible areas)

Cable diameter: 2-pole: 5–9 mm Ø, 7–10.5 mm Ø

3-pole: 4.5–8 mm Ø, 8–11.5 mm Ø, 9–13 mm Ø

4-pole: 9–13 mm Ø

5-pole: 5–9 mm Ø, 9–13 mm Ø, 11.5–16.5 mm Ø

6-pole: 8.5–13.5 mm Ø

7-pole: 8–15 mm Ø

Mating cycles: 200, without resistive load

100, with resistive load I = 25 A, tested (4 mm /12 AWG)

2

N

Mating and unmating forces: Mating force: approx. 20–70 N (depending on number of poles)

(socket and plug) Unmating force when unlocked: approx. 20–70 N (depending on number of poles)

Retention force when locked: > 80 N

Protection against mismating: All WINSTA components are 100% protected against mismating in terms of:

®

a.) plugging different number of poles

b.) plugging when turned by 180°

c.) plugging when laterally staggered

d.) plugging one pole

Locking levers: All connectors for fixed installations (snap-in versions for lighting fixtures, devices or all

types of PCBs and distribution cabinets) are factory-equipped with locking levers to en-

sure plugs and sockets are securely locked. Additional locking levers are only required

for “flying leads” (plug/socket).

Materials: Connector material

Insulating parts: Polyamide 6.6 V0, halogen-free (except cable)

Contacts: Copper or copper alloy, surface-treated

Clamping spring: Stainless steel (Cr-Ni)

Processing temperature: –5°C to +40°C

Continuous operating temperature: –35°C to ≤ 85°C

PVC cable for temperatures ≤ 70 °C (including halogen-free)

Insulating parts for temperatures ≤ 105 °C

General: First make/last break ground contacts

Fire load: upon request