Page 604 - Wago_PCB_TerminalBlocksConnectors_Volume2_2015_US

P. 604

13 Tests and Testing Procedures per IEC/EN Standards (continued)

602

Environmental Tests

The following tests show how a product reacts when exposed to an aggressive environment. Climatic chambers simulate standard

atmospheres that could impact long-term constancy of clamping units.

All WAGO products meet requirements for the following environmental tests:

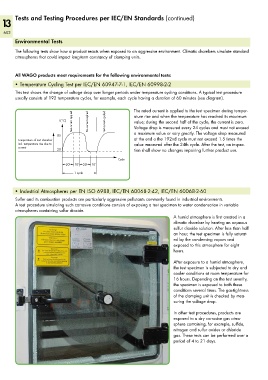

• Temperature Cycling Test per IEC/EN 60947-7-1, IEC/EN 60998-2-2

This test shows the change of voltage drop over longer periods under temperature cycling conditions. A typical test procedure

usually consists of 192 temperature cycles, for example, each cycle having a duration of 60 minutes (see diagram).

The rated current is applied to the test specimen during temper-

Test current applied No current applied Test current applied value; during the second half of the cycle, the current is zero.

T (°C) ature rise and when the temperature has reached its maximum

Voltage drop is measured every 24 cycles and must not exceed

85 a maximum value or vary greatly. The voltage drop measured

Temperature of test chamber at the end o the 192nd cycle must not exceed 1.5 times the

incl. temperature rise due to value measured after the 24th cycle. After the test, an inspec-

current

20 tion shall show no changes impairing further product use.

Cycle

<20’> 10’ <20’> 10’

<_____ 1 cycle _____>

• Industrial Atmospheres per EN ISO 6988, IEC/EN 60068-2-42, IEC/EN 60068-2-60

Sulfur and its combustion products are particularly aggressive pollutants commonly found in industrial environments.

A test procedure simulating such corrosive conditions consists of exposing a test specimen to water condensation in variable

atmospheres containing sulfur dioxide.

A humid atmosphere is first created in a

climatic chamber by heating an aqueous

sulfur dioxide solution. After less than half

an hour, the test specimen is fully saturat-

ed by the condensing vapors and

exposed to this atmosphere for eight

hours.

After exposure to a humid atmosphere,

the test specimen is subjected to dry and

cooler conditions at room temperature for

16 hours. Depending on the test severity,

the specimen is exposed to both these

conditions several times. The gas-tightness

of the clamping unit is checked by mea-

suring the voltage drop.

In other test procedures, products are

exposed to a dry corrosive gas atmo-

sphere containing, for example, sulfide,

nitrogen and sulfur oxides or chloride

gas. These tests can be performed over a

period of 4 to 21 days.