Page 357 - Brass, Composite and Thermoplastic Fittings and Valves

P. 357

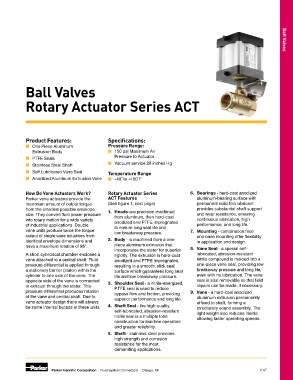

Ball Valves Ball Valves

Rotary Actuator Series ACT

Product Features: Specifications:

■ One Piece Aluminum Pressure Range:

Extrusion Body ■ 150 psi Maximum Air

■ PTFE Seals Pressure to Actuator

■ Stainless Steel Shaft ■ Vacuum service 28 inches Hg

■ Self Lubricated Vane Seal Temperature Range

■ Anodized Aluminum Extrusion Vane ■ -40˚ to +180˚F

How Do Vane Actuators Work? Rotary Actuator Series 6. Bearings - hard-coat anodized

Parker vane actuators provide the ACT Features aluminum-bearing surface with

maximum amount of output torque (See figure 1, next page) permanent solid film lubricant

from the smallest possible envelope 1. Heads-are precision machined provides substantial shaft support

size. They convert fluid power pressure from aluminum, then hard-coat and wear resistance, ensuring

into rotary motion for a wide variety anodized and PTFE impregnated continuous lubrication, high

of industrial applications. Double to ensure long seal life and performance, and long life.

vane units produce twice the torque low breakaway pressure. 7. Mounting - combination face

output of single vane actuators from and base mounting offer flexibility

identical envelope dimensions and 2. Body - is machined from a one- in application and design.

have a maximum rotation of 95°. piece aluminum extrusion that

incorporates the stator for superior 8. Vane Seal - a special self-

A short cylindrical chamber encloses a rigidity. The extrusion is hard-coat lubricated, abrasion-resistant

vane attached to a central shaft. Fluid anodized and PTFE impregnated, nitrile compound is molded into a

pressure differential is applied through resulting in a smooth, slick seal one-piece vane seal, providing low

a stationary barrier (stator) within the surface which guarantees long seal breakaway pressure and long life,

cylinder to one side of the vane. The life and low breakaway pressure. even with no lubrication. The vane

opposite side of the vane is connected 3. Shoulder Seal - a nitrile-energized, seal is also removable so that field

to exhaust through the stator. This PTFE seal is used to reduce repairs can be made, if necessary.

pressure differential produces rotation bypass flow and friction, providing 9. Vane - a hard-coat anodized

of the vane and central shaft. Due to superior performance and long life. aluminum extrusion permanently

vane actuator design there will always affixed to shaft, forming a

be some internal bypass in these units. 4. Shaft Seal - the high-quality, structurally sound assembly. The

self-lubricated, abrasion-resistant light weight also reduces inertia

nitrile seal is a multiple lobe allowing faster operating speeds.

construction for leakfree operation

and greater reliability.

5. Shaft - stainless steel provides

high strength and corrosion

resistance for the most

demanding applications.

Parker Hannifin Corporation | Fluid System Connectors | Otsego, MI K47