Page 124 - Parker - Polyflex Hose Products (Ultra High Pressure Thermoplastic Hose)

P. 124

Catalog 4900 polyflex ®

Hose and Fittings 2700 Series

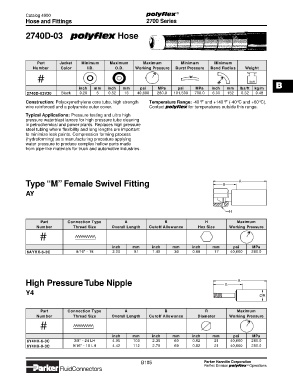

2740D-03 polyflex Hose

Part Jacket Minimum Maximum Maximum Minimum Minimum

Number Color I.D. O.D. Working Pressure Burst Pressure Bend Radius Weight

B

inch mm inch mm psi MPa psi MPa inch mm lbs/ft kg/m

2740D-03V30 Black 0.20 5 0.52 13 40,600 280.0 101,500 700.0 6.00 152 0.32 0.48

Construction: Polyoxymethylene core tube, high strength Temperature Range: -40°F and +140°F (-40°C and +60°C).

wire reinforced and a polyamide outer cover. Contact polyflex for temperatures outside this range.

Typical Applications: Pressure testing and ultra high

pressure waterblast lances for high pressure tube cleaning

in petrochemical and power plants. Replaces high pressure

steel tubing where flexibility and long lengths are important

to minimize leak points. Compression forming process

(hydroforming) as a manufacturing procedure applying

water pressure to produce complex hollow parts made

from pipe-like materials for truck and automotive industries.

Type “M” Female Swivel Fitting B A

AY

H

Part Connection Type A B H Maximum

Number Thread Size Overall Length Cutoff Allowance Hex Size Working Pressure

inch mm inch mm inch mm psi MPa

6AYHX-6-3C 9/16" - 18 3.20 81 1.40 36 0.68 17 40,600 280.0

High Pressure Tube Nipple B A

Y4

ØR

Part Connection Type A B R Maximum

Number Thread Size Overall Length Cutoff Allowance Diameter Working Pressure

inch mm inch mm inch mm psi MPa

6Y4HX-6-3C 3/8" - 24 LH 4.05 103 2.36 60 0.82 21 40,600 280.0

6Y4HX-9-3C 9/16" - 18 LH 4.42 112 2.70 69 0.82 21 40,600 280.0

B105 Parker Hannifin Corporation

Parflex Division polyflex Operations

®

FluidConnectors