Page 7 - Exlar - Hazardous location GSX/GSM class 1 division 2

P. 7

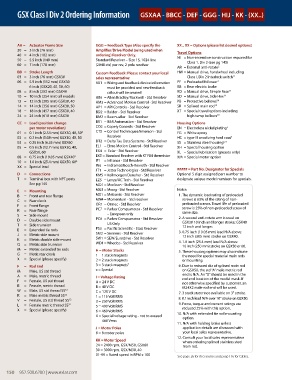

GSX Class I Div 2 Ordering Information GSXAA - BBCC - DEF - GGG - HIJ - KK - (XX..)

AA = Actuator Frame Size GGG = Feedback Type (Also specify the XX .. XX = Options (please list desired options)

30 = 3 inch (76 mm) Amplifier/Drive Model being used when Travel Options

40 = 4 inch (102 mm) ordering) Resolver Only. NI = Non-incendive construction required for

50 = 5.5 inch (140 mm) Standard Resolver – Size 15, 1024 line Class 1, Div 2 (see pg 145)

60 = 7 inch (178 mm) (2048 cts) per rev, 2 pole resolver

AR = External anti-rotate 2

BB = Stroke Length Custom Feedback: Please contact your local HW = Manual drive, handwheel including

03 = 3 inch (76 mm) GSX30 sales representative: Class I, Div 2 interlock switch 11

06 = 5.9 inch (152 mm) GSX30 XX1 = Wiring and feedback device information PF = Preloaded follower 1

6 inch (GSX20, 40, 50, 60) must be provided and new feedback RB = Rear electric brake

08 = 8 inch (203 mm) GSX40 callout will be created RD = Manual drive, Simple Rear 11

10 = 10 inch (254 mm) all models AB6 = Allen Bradley/Rockwell - Std Resolver SD = Manual drive, Side Hex 11

12 = 12 inch (305 mm) GSX30, 40 AM3 = Advanced Motion Control - Std Resolver PB = Protective bellows 10

14 = 14 inch (356 mm) GSX30, 50 AP1 = API Controls - Std Resolver SR = Splined main rod 12

18 = 18 inch (457 mm) GSX30, 40 BD2 = Baldor - Std Resolver XT = Special travel options including

24 = 24 inch (610 mm) GSX30 BM2 = Baumueller - Std Resolver high temp bellows 10

CC = Lead (position change BR1 = B&R Automation - Std Resolver Housing Options

per motor revolution) CO2 = Copely Controls - Std Resolver EN = Electroless nickel plating

5

01 = 0.1 inch (2.54 mm) GSX30, 40, 50 8 CT5 = Control Techniques/Emerson - Std FG = White epoxy

02 = 0.2 inch (5.08 mm) GSX30, 40, 50 Resolver HC = type III anodizing hard coat 5

03 = 0.25 inch (6.35 mm) GSX60 DT2 = Delta Tau Data Systems - Std Resolver SS = Stainless steel housing 5, 9

05 = 0.5 inch (12.7 mm) GSX30, 40, EL1 = Elmo Motion Control - Std Resolver XH = Special housing option

GSX50, 60 EX4 = Exlar - Std Resolver XL = Special lubrication (greases only)

08 = 0.75 inch (19.05 mm) GSX40 3 EX5 = Standard Resolver with KTY84 thermistor XM = Special motor option

10 = 1.0 inch (25.4 mm) GSX50, 60 4 IF1 = Infranor - Std Resolver

XX = Special lead IN6 = Indramat/Bosch-Rexroth - Std Resolver

JT1 = Jetter Technologies - Std Resolver ##### = Part No. Designator for Specials

D = Connections KM5 = Kollmorgen/Danaher - Std Resolver Optional 5 digit assigned part number to

T = Terminal box with NPT ports LZ5 = Lenze/AC Tech - Std Resolver designate unique model numbers for specials.

See pg 145 MD1 = Modicon - Std Resolver

E = Mounting MG1 = Moog - Std Resolver Notes:

B = Front and rear flange MX1 = Metronix - Std Resolver 1. The dynamic load rating of preloaded

C = Rear clevis MN4 = Momentum - Std resolver screws is 63% of the rating of non-

F = Front flange OR1 = Ormec - Std Resolver preloaded screws. Travel life of preloaded

screw is 25% of non-preloaded screw of

R = Rear flange PC7 = Parker Compumotor - Std Resolver same size.

S = Side mount – European only 2. A second anti-rotate arm is used on

D = Double side mount PC0 = Parker Compumotor - Std Resolver – GSX30 10 inch and longer stroke; GSX40

T = Side trunnion US Only 12 inch and longer.

E = Extended tie rods PS3 = Pacific Scientific - Stad Resolver 3. 0.75 inch (19.05 mm) lead N/A above

J = Metric side mount SM2 = Siemens - Std Resolver 12 inch (305 mm) stroke on GSX40.

K = Metric double side mount SW1 = SEW/Eurodrive - Std Resolver 4. 1.0 inch (25.4 mm) lead N/A above

Q = Metric side trunnion WD1 = Whedco - Std Resolver 10 inch (250 mm) stroke on GSX50 or 60.

M = Metric extended tie rods H = Motor Stacks 5. These housing options may also indicate

G = Metic rear clevis 1 = 1 stack magnets the need for special material main rods

X = Special (please specify) 2 = 2 stack magnets or mounting.

F = Rod End 3 = 3 stack magnets 7 6. Due to reduced dia of splined main rod

M = Male, US std thread x = Special on GSX50, the std “A” male metric rod

A = Male, metric thread I = Voltage Rating end is N/A. An “X” should be used in the

F = Female, US std thread A = 24 V DC rod end location of the model mask. If

not otherwise specified by customer, an

B = Female, metric thread B = 48 V DC M24X2 male rod end will be used.

W = Male, US std thread SS 12 C = 120 V DC 7. 3 stack stator not available on 3" stroke.

R = Male metric thread SS 12 1 = 115 Volt RMS

V = Female, US std thread SS 12 3 = 230 Volt RMS 8. 0.1 inch lead N/A over 10" stroke on GSX50.

L = Female metric thread SS 12 5 = 400 Volt RMS 9. Force, torque and current ratings are

X = Special (please specify) 6 = 460 Volt RMS reduced 25% with this option.

X = Special voltage rating - not to exceed 10. N/A with extended tie rod mounting

option.

460 Vrms

11. N/A with holding brake unless

J = Motor Poles application details are discussed with

8 = 8 motor poles your local sales representative.

12. Consult your local sales representative

KK = Motor Speed when ordering splined stainless steel

24 = 2400 rpm, GSX/M50, GSX60 main rod.

30 = 3000 rpm, GSX/M30, 40

01-99 = Rated speed in RPM x 100 See page 26 for Accessories and page 116 for Cables.

150

150 952.500.6200 | www.exlar.com 952.500.6200 | www.exlar.com