Page 446 - Mechatronics with Experiments

P. 446

JWST499-Cetinkunt

JWST499-c07

432 MECHATRONICS Printer: Yet to Come October 9, 2014 8:41 254mm×178mm

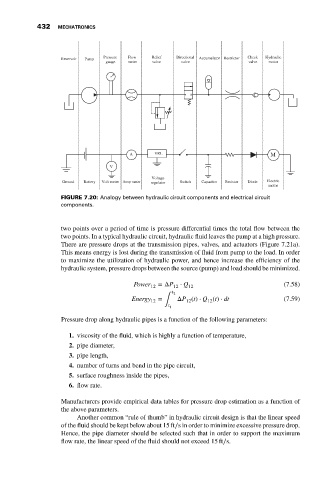

Pressure Flow Relief Directional Check Hydraulic

Reservoir Pump Accumulator Restrictor

gauge meter valve valve valve motor

A VRL M

V

Voltage

Ground Battery Volt meter Amp meter regulator Switch Capacitor Resistor Diode Electric

motor

FIGURE 7.20: Analogy between hydraulic circuit components and electrical circuit

components.

two points over a period of time is pressure differential times the total flow between the

two points. In a typical hydraulic circuit, hydraulic fluid leaves the pump at a high pressure.

There are pressure drops at the transmission pipes, valves, and actuators (Figure 7.21a).

This means energy is lost during the transmission of fluid from pump to the load. In order

to maximize the utilization of hydraulic power, and hence increase the efficiency of the

hydraulic system, pressure drops between the source (pump) and load should be minimized.

Power 12 =ΔP 12 ⋅ Q 12 (7.58)

t 2

Energy = ΔP (t) ⋅ Q (t) ⋅ dt (7.59)

12 ∫ 12 12

t 1

Pressure drop along hydraulic pipes is a function of the following parameters:

1. viscosity of the fluid, which is highly a function of temperature,

2. pipe diameter,

3. pipe length,

4. number of turns and bend in the pipe circuit,

5. surface roughness inside the pipes,

6. flow rate.

Manufacturers provide empirical data tables for pressure drop estimation as a function of

the above parameters.

Another common “rule of thumb” in hydraulic circuit design is that the linear speed

of the fluid should be kept below about 15 ft∕s in order to minimize excessive pressure drop.

Hence, the pipe diameter should be selected such that in order to support the maximum

flow rate, the linear speed of the fluid should not exceed 15 ft∕s.