Page 814 - Mechatronics with Experiments

P. 814

800 MECHATRONICS

+5 VDC +5 VDC

100 Ω

+

+

E To microcontroller

100 kΩ

Opto interruptor

(Opto coupler)

2 Opto-interrupters

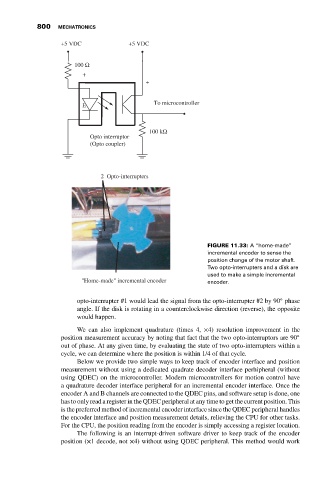

FIGURE 11.33: A “home-made”

incremental encoder to sense the

position change of the motor shaft.

Two opto-interrupters and a disk are

used to make a simple incremental

"Home-made" incremental encoder encoder.

◦

opto-interrupter #1 would lead the signal from the opto-interrupter #2 by 90 phase

angle. If the disk is rotating in a counterclockwise direction (reverse), the opposite

would happen.

We can also implement quadrature (times 4, ×4) resolution improvement in the

position measurement accuracy by noting that fact that the two opto-interruptors are 90 ◦

out of phase. At any given time, by evaluating the state of two opto-interrupters within a

cycle, we can determine where the position is within 1/4 of that cycle.

Below we provide two simple ways to keep track of encoder interface and position

measurement without using a dedicated quadrate decoder interface perhipheral (without

using QDEC) on the microcontroller. Modern microcontrollers for motion control have

a quadrature decoder interface peripheral for an incremental encoder interface. Once the

encoder A and B channels are connected to the QDEC pins, and software setup is done, one

has to only read a register in the QDEC peripheral at any time to get the current position. This

is the preferred method of incremental encoder interface since the QDEC peripheral handles

the encoder interface and position measurement details, relieving the CPU for other tasks.

For the CPU, the position reading from the encoder is simply accessing a register location.

The following is an interrupt-driven software driver to keep track of the encoder

position (×1 decode, not ×4) without using QDEC peripheral. This method would work