Page 682 - Most-Essential-Learning-Competencies-Matrix-LATEST-EDITION-FROM-BCD

P. 682

682

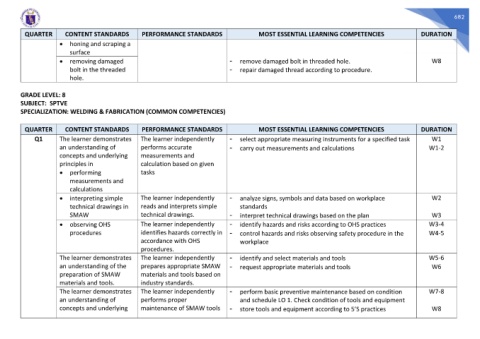

QUARTER CONTENT STANDARDS PERFORMANCE STANDARDS MOST ESSENTIAL LEARNING COMPETENCIES DURATION

• honing and scraping a

surface

• removing damaged - remove damaged bolt in threaded hole. W8

bolt in the threaded - repair damaged thread according to procedure.

hole.

GRADE LEVEL: 8

SUBJECT: SPTVE

SPECIALIZATION: WELDING & FABRICATION (COMMON COMPETENCIES)

QUARTER CONTENT STANDARDS PERFORMANCE STANDARDS MOST ESSENTIAL LEARNING COMPETENCIES DURATION

Q1 The learner demonstrates The learner independently - select appropriate measuring instruments for a specified task W1

an understanding of performs accurate - carry out measurements and calculations W1-2

concepts and underlying measurements and

principles in calculation based on given

• performing tasks

measurements and

calculations

• interpreting simple The learner independently - analyze signs, symbols and data based on workplace W2

technical drawings in reads and interprets simple standards

SMAW technical drawings. - interpret technical drawings based on the plan W3

• observing OHS The learner independently - identify hazards and risks according to OHS practices W3-4

procedures identifies hazards correctly in - control hazards and risks observing safety procedure in the W4-5

accordance with OHS workplace

procedures.

The learner demonstrates The learner independently - identify and select materials and tools W5-6

an understanding of the prepares appropriate SMAW - request appropriate materials and tools W6

preparation of SMAW materials and tools based on

materials and tools. industry standards.

The learner demonstrates The learner independently - perform basic preventive maintenance based on condition W7-8

an understanding of performs proper and schedule LO 1. Check condition of tools and equipment

concepts and underlying maintenance of SMAW tools - store tools and equipment according to 5’S practices W8