Page 681 - Most-Essential-Learning-Competencies-Matrix-LATEST-EDITION-FROM-BCD

P. 681

681

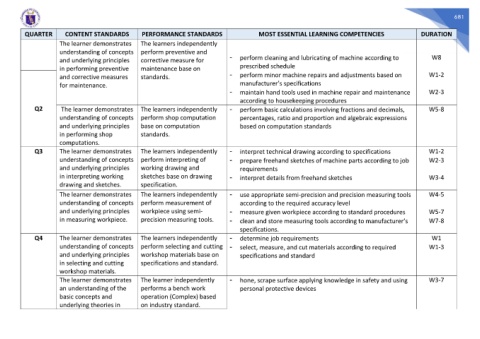

QUARTER CONTENT STANDARDS PERFORMANCE STANDARDS MOST ESSENTIAL LEARNING COMPETENCIES DURATION

The learner demonstrates The learners independently

understanding of concepts perform preventive and

and underlying principles corrective measure for - perform cleaning and lubricating of machine according to W8

in performing preventive maintenance base on prescribed schedule

and corrective measures standards. - perform minor machine repairs and adjustments based on W1-2

for maintenance. manufacturer’s specifications

- maintain hand tools used in machine repair and maintenance W2-3

according to housekeeping procedures

Q2 The learner demonstrates The learners independently - perform basic calculations involving fractions and decimals, W5-8

understanding of concepts perform shop computation percentages, ratio and proportion and algebraic expressions

and underlying principles base on computation based on computation standards

in performing shop standards.

computations.

Q3 The learner demonstrates The learners independently - interpret technical drawing according to specifications W1-2

understanding of concepts perform interpreting of - prepare freehand sketches of machine parts according to job W2-3

and underlying principles working drawing and requirements

in interpreting working sketches base on drawing - interpret details from freehand sketches W3-4

drawing and sketches. specification.

The learner demonstrates The learners independently - use appropriate semi-precision and precision measuring tools W4-5

understanding of concepts perform measurement of according to the required accuracy level

and underlying principles workpiece using semi- - measure given workpiece according to standard procedures W5-7

in measuring workpiece. precision measuring tools. - clean and store measuring tools according to manufacturer’s W7-8

specifications.

Q4 The learner demonstrates The learners independently - determine job requirements W1

understanding of concepts perform selecting and cutting - select, measure, and cut materials according to required W1-3

and underlying principles workshop materials base on specifications and standard

in selecting and cutting specifications and standard.

workshop materials.

The learner demonstrates The learner independently - hone, scrape surface applying knowledge in safety and using W3-7

an understanding of the performs a bench work personal protective devices

basic concepts and operation (Complex) based

underlying theories in on industry standard.