Page 40 - April 2023

P. 40

The Fixit Corner continues from page 39

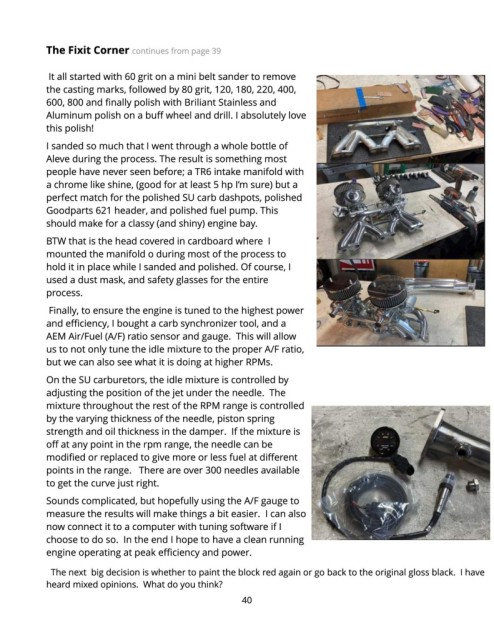

It all started with 60 grit on a mini belt sander to remove

the casting marks, followed by 80 grit, 120, 180, 220, 400,

600, 800 and finally polish with Briliant Stainless and

Aluminum polish on a buff wheel and drill. I absolutely love

this polish!

I sanded so much that I went through a whole bottle of

Aleve during the process. The result is something most

people have never seen before; a TR6 intake manifold with

a chrome like shine, (good for at least 5 hp I?m sure) but a

perfect match for the polished SU carb dashpots, polished

Goodparts 621 header, and polished fuel pump. This

should make for a classy (and shiny) engine bay.

BTW that is the head covered in cardboard where I

mounted the manifold o during most of the process to

hold it in place while I sanded and polished. Of course, I

used a dust mask, and safety glasses for the entire

process.

Finally, to ensure the engine is tuned to the highest power

and efficiency, I bought a carb synchronizer tool, and a

AEM Air/Fuel (A/F) ratio sensor and gauge. This will allow

us to not only tune the idle mixture to the proper A/F ratio,

but we can also see what it is doing at higher RPMs.

On the SU carburetors, the idle mixture is controlled by

adjusting the position of the jet under the needle. The

mixture throughout the rest of the RPM range is controlled

by the varying thickness of the needle, piston spring

strength and oil thickness in the damper. If the mixture is

off at any point in the rpm range, the needle can be

modified or replaced to give more or less fuel at different

points in the range. There are over 300 needles available

to get the curve just right.

Sounds complicated, but hopefully using the A/F gauge to

measure the results will make things a bit easier. I can also

now connect it to a computer with tuning software if I

choose to do so. In the end I hope to have a clean running

engine operating at peak efficiency and power.

The next big decision is whether to paint the block red again or go back to the original gloss black. I have

heard mixed opinions. What do you think?

40