Page 9 - Georgia Markham

P. 9

7. Project 12: Redesign Cookworks Hand Mixer Designs

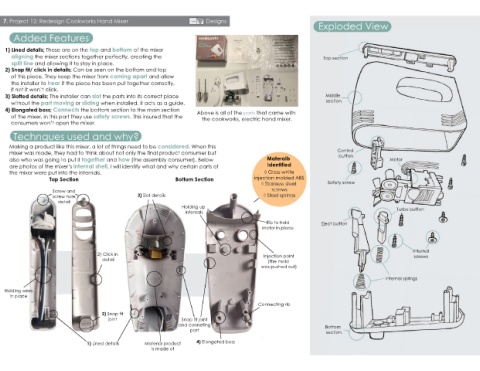

Exploded View

Added Features

1) Lined details; These are on the top and bottom of the mixer

aligning the mixer sections together perfectly, creating the Top section

split line and allowing it to stay in place.

2) Snap fit/ click in details; Can be seen on the bottom and top

of this piece. They keep the mixer from coming apart and allow

the installer to hear if the piece has been put together correctly,

if not it won’t click.

3) Slotted details; The installer can slot the parts into its correct place Middle

without the part moving or sliding when installed, it acts as a guide. section

4) Elongated boss; Connects the bottom section to the main section Above is all of the parts that came with

of the mixer, in this part they use safety screws. This insured that the the cookworks, electric hand mixer.

consumers won’t open the mixer.

Technques used and why?

Making a product like this mixer, a lot of things need to be considered. When this

mixer was made, they had to think about not only the final product consumer but Control

button

also who was going to put it together and how (the assembly consumer). Below Materails Motor

are photos of the mixer’s internal shell, I will identify what and why certain parts of Identified

the mixer were put into the internals. ◊ Gloss white

Top Section Bottom Section injection molded ABS

◊ Stainless steel Safety screw

Screw and screws

screw hole 3) Slot details ◊ Steel springs

detail

Holding up Turbo button

internals

Rib to hold Eject button

motor in place

Internal

2) Click in Injection point screws

detail (the mold

was pushed out)

Internal springs

Holding wires

in place

Connecting rib

2) Snap fit

joint Snap fit joint

and conneting Bottom

part

section

1) Lined details Material product 4) Elongated boss

is made of