Page 37 - RCM - A practical Guide_V1

P. 37

RCM - A Practical Guide

Task selection

Once OC maintenance has been identified as applicable, and the analysis understands the potential

failure condition, it must then design the task itself and it will consider all techniques capable of

detecting the potential failure condition.

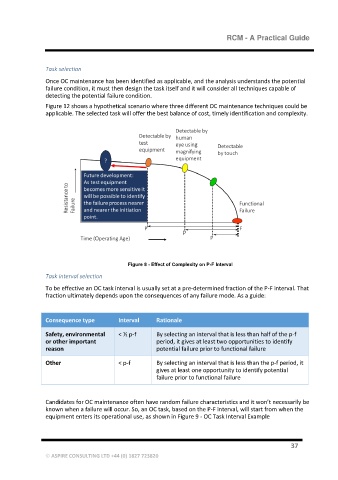

Figure 12 shows a hypothetical scenario where three different OC maintenance techniques could be

applicable. The selected task will offer the best balance of cost, timely identification and complexity.

Figure 8 - Effect of Complexity on P-F Interval

Task interval selection

To be effective an OC task interval is usually set at a pre-determined fraction of the P-F interval. That

fraction ultimately depends upon the consequences of any failure mode. As a guide:

Consequence type Interval Rationale

Safety, environmental < ½ p-f By selecting an interval that is less than half of the p-f

or other important period, it gives at least two opportunities to identify

reason potential failure prior to functional failure

Other < p-f By selecting an interval that is less than the p-f period, it

gives at least one opportunity to identify potential

failure prior to functional failure

Candidates for OC maintenance often have random failure characteristics and it won’t necessarily be

known when a failure will occur. So, an OC task, based on the P-F interval, will start from when the

equipment enters its operational use, as shown in Figure 9 - OC Task Interval Example

37

© ASPIRE CONSULTING LTD +44 (0) 1827 723820