Page 5 - Toro Product Guide_2020.cdr

P. 5

Rotary Angle Broom RAB-3280D

Fits Toro Groundsmaster 3280D

Commercial Grade Construction

- The main pivot and mount frames are contructed from

1/4" and 3/8" laser cut steel.

- The center pivot pin is 1-1/2" OD 4140 hardened solid

rod. It is supported by two brass bushings and is

serviceable with a grease nipple.

- The broom hood is formed from 12-gauge steel plate.

- The broom head side plates are constructed from 1/4"

laser cut steel plate.

- The broom head side plates are connected with a 2-1/2"

square tube with a 1/4" wall.

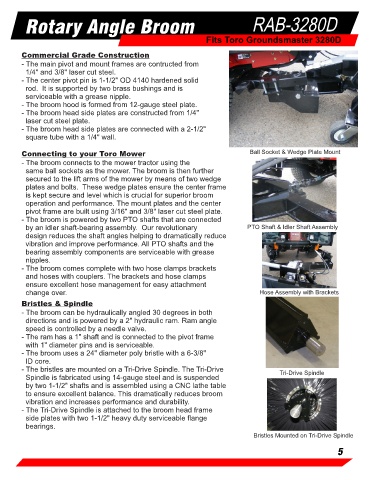

Connecting to your Toro Mower Ball Socket & Wedge Plate Mount

- The broom connects to the mower tractor using the

same ball sockets as the mower. The broom is then further

secured to the lift arms of the mower by means of two wedge

plates and bolts. These wedge plates ensure the center frame

is kept secure and level which is crucial for superior broom

operation and performance. The mount plates and the center

pivot frame are built using 3/16" and 3/8" laser cut steel plate.

- The broom is powered by two PTO shafts that are connected

by an idler shaft-bearing assembly. Our revolutionary PTO Shaft & Idler Shaft Assembly

design reduces the shaft angles helping to dramatically reduce

vibration and improve performance. All PTO shafts and the

bearing assembly components are serviceable with grease

nipples.

- The broom comes complete with two hose clamps brackets

and hoses with couplers. The brackets and hose clamps

ensure excellent hose management for easy attachment

change over. Hose Assembly with Brackets

Bristles & Spindle

- The broom can be hydraulically angled 30 degrees in both

directions and is powered by a 2" hydraulic ram. Ram angle

speed is controlled by a needle valve.

- The ram has a 1" shaft and is connected to the pivot frame

with 1" diameter pins and is serviceable.

- The broom uses a 24" diameter poly bristle with a 6-3/8"

ID core.

- The bristles are mounted on a Tri-Drive Spindle. The Tri-Drive Tri-Drive Spindle

Spindle is fabricated using 14-gauge steel and is suspended

by two 1-1/2" shafts and is assembled using a CNC lathe table

to ensure excellent balance. This dramatically reduces broom

vibration and increases performance and durability.

- The Tri-Drive Spindle is attached to the broom head frame

side plates with two 1-1/2" heavy duty serviceable flange

bearings.

Bristles Mounted on Tri-Drive Spindle

5