Page 13 - June 2022 Track N Times

P. 13

TECHNICAL TRAINING

The Need to Create Work Order Return Lines

By: Brian Denker, Manager, Enterprise Asset Management System

Work order return lines are one of those necessary parts of the work order when your work requires replacing a

grind motor, dust blower, traction motor, engine, generator, engine/genset package, desiccant canister assemblies,

etc. You get the idea – every time the work requires replacing an item that is serialized, and the removed item

needs to go somewhere to get rebuilt, a return line on the work order is required!

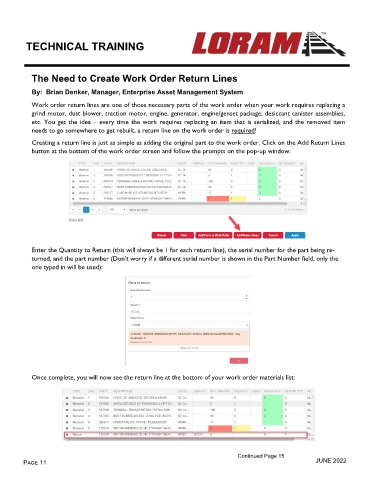

Creating a return line is just as simple as adding the original part to the work order. Click on the Add Return Lines

button at the bottom of the work order screen and follow the prompts on the pop-up window:

Enter the Quantity to Return (this will always be 1 for each return line), the serial number for the part being re-

turned, and the part number (Don’t worry if a different serial number is shown in the Part Number field, only the

one typed in will be used):

Once complete, you will now see the return line at the bottom of your work order materials list:

Continued Page 15

Page 11 JUNE 2022