Page 31 - Апрель

P. 31

FOUNDRY PRODUCTION

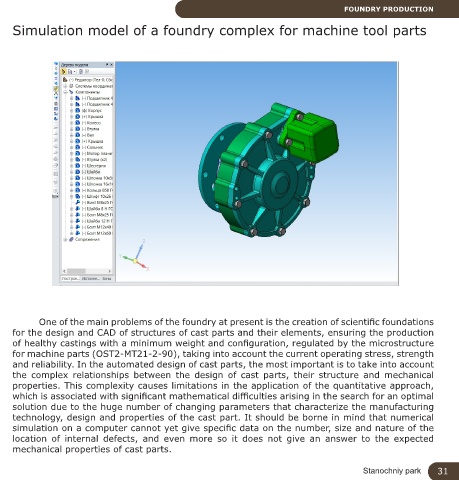

Simulation model of a foundry complex for machine tool parts

One of the main problems of the foundry at present is the creation of scientific foundations

for the design and CAD of structures of cast parts and their elements, ensuring the production

of healthy castings with a minimum weight and configuration, regulated by the microstructure

for machine parts (OST2-MT21-2-90), taking into account the current operating stress, strength

and reliability. In the automated design of cast parts, the most important is to take into account

the complex relationships between the design of cast parts, their structure and mechanical

properties. This complexity causes limitations in the application of the quantitative approach,

which is associated with significant mathematical difficulties arising in the search for an optimal

solution due to the huge number of changing parameters that characterize the manufacturing

technology, design and properties of the cast part. It should be borne in mind that numerical

simulation on a computer cannot yet give specific data on the number, size and nature of the

location of internal defects, and even more so it does not give an answer to the expected

mechanical properties of cast parts.

Stanochniy park 31