Page 59 - Towards A Sustainable Future 2024

P. 59

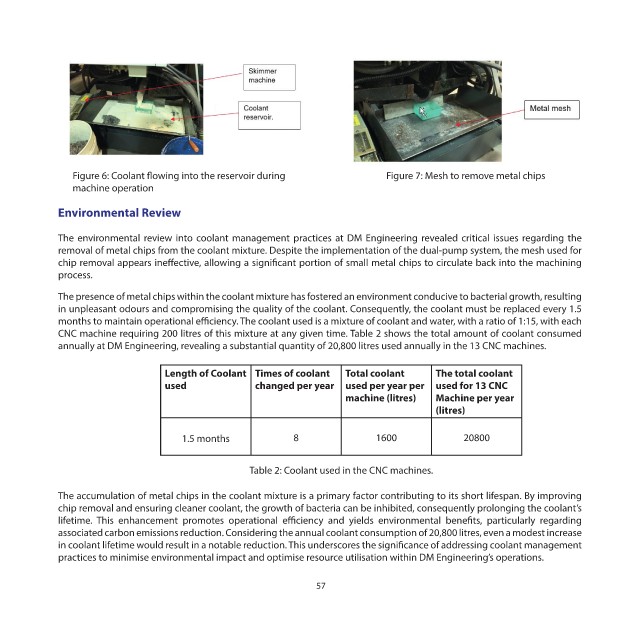

Figure 6: Coolant flowing into the reservoir during Figure 7: Mesh to remove metal chips

machine operation

Environmental Review

The environmental review into coolant management practices at DM Engineering revealed critical issues regarding the

removal of metal chips from the coolant mixture. Despite the implementation of the dual-pump system, the mesh used for

chip removal appears ineffective, allowing a significant portion of small metal chips to circulate back into the machining

process.

The presence of metal chips within the coolant mixture has fostered an environment conducive to bacterial growth, resulting

in unpleasant odours and compromising the quality of the coolant. Consequently, the coolant must be replaced every 1.5

months to maintain operational efficiency. The coolant used is a mixture of coolant and water, with a ratio of 1:15, with each

CNC machine requiring 200 litres of this mixture at any given time. Table 2 shows the total amount of coolant consumed

annually at DM Engineering, revealing a substantial quantity of 20,800 litres used annually in the 13 CNC machines.

Length of Coolant Times of coolant Total coolant The total coolant

used changed per year used per year per used for 13 CNC

machine (litres) Machine per year

(litres)

1.5 months 8 1600 20800

Table 2: Coolant used in the CNC machines.

The accumulation of metal chips in the coolant mixture is a primary factor contributing to its short lifespan. By improving

chip removal and ensuring cleaner coolant, the growth of bacteria can be inhibited, consequently prolonging the coolant’s

lifetime. This enhancement promotes operational efficiency and yields environmental benefits, particularly regarding

associated carbon emissions reduction. Considering the annual coolant consumption of 20,800 litres, even a modest increase

in coolant lifetime would result in a notable reduction. This underscores the significance of addressing coolant management

practices to minimise environmental impact and optimise resource utilisation within DM Engineering’s operations.

57