Page 63 - Towards A Sustainable Future 2024

P. 63

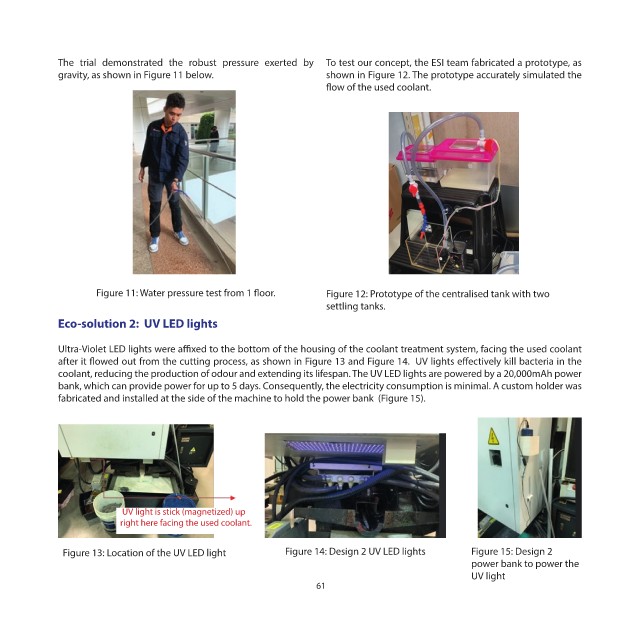

The trial demonstrated the robust pressure exerted by To test our concept, the ESI team fabricated a prototype, as

gravity, as shown in Figure 11 below. shown in Figure 12. The prototype accurately simulated the

flow of the used coolant.

Figure 11: Water pressure test from 1 floor. Figure 12: Prototype of the centralised tank with two

settling tanks.

Eco-solution 2: UV LED lights

Ultra-Violet LED lights were affixed to the bottom of the housing of the coolant treatment system, facing the used coolant

after it flowed out from the cutting process, as shown in Figure 13 and Figure 14. UV lights effectively kill bacteria in the

coolant, reducing the production of odour and extending its lifespan. The UV LED lights are powered by a 20,000mAh power

bank, which can provide power for up to 5 days. Consequently, the electricity consumption is minimal. A custom holder was

fabricated and installed at the side of the machine to hold the power bank (Figure 15).

UV light is stick (magnetized) up

right here facing the used coolant.

Figure 13: Location of the UV LED light Figure 14: Design 2 UV LED lights Figure 15: Design 2

power bank to power the

UV light

61