Page 60 - Towards A Sustainable Future 2024

P. 60

Eco- Solution

An eco-friendly solution involving adopting a sedimentation process in coolant management was proposed to address the

challenge of prolonging coolant lifetime and reducing bacterial growth. The objective was to enhance the effectiveness of

chip removal from the coolant, thereby mitigating the conditions favourable for bacterial growth.

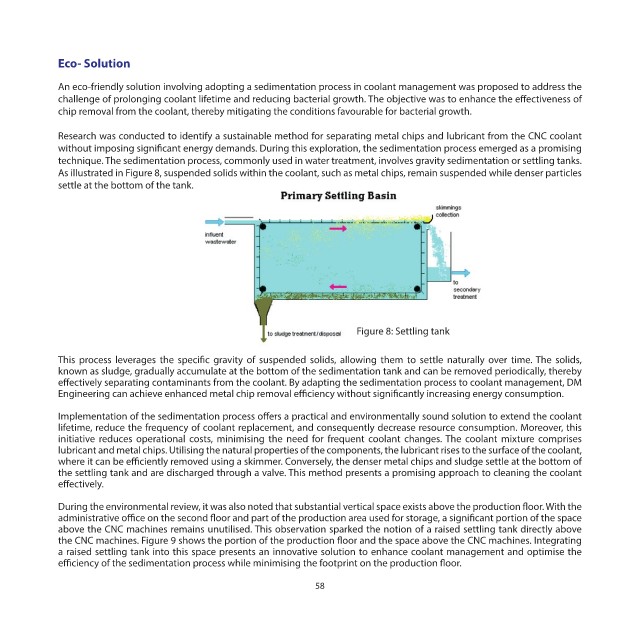

Research was conducted to identify a sustainable method for separating metal chips and lubricant from the CNC coolant

without imposing significant energy demands. During this exploration, the sedimentation process emerged as a promising

technique. The sedimentation process, commonly used in water treatment, involves gravity sedimentation or settling tanks.

As illustrated in Figure 8, suspended solids within the coolant, such as metal chips, remain suspended while denser particles

settle at the bottom of the tank.

Figure 8: Settling tank

This process leverages the specific gravity of suspended solids, allowing them to settle naturally over time. The solids,

known as sludge, gradually accumulate at the bottom of the sedimentation tank and can be removed periodically, thereby

effectively separating contaminants from the coolant. By adapting the sedimentation process to coolant management, DM

Engineering can achieve enhanced metal chip removal efficiency without significantly increasing energy consumption.

Implementation of the sedimentation process offers a practical and environmentally sound solution to extend the coolant

lifetime, reduce the frequency of coolant replacement, and consequently decrease resource consumption. Moreover, this

initiative reduces operational costs, minimising the need for frequent coolant changes. The coolant mixture comprises

lubricant and metal chips. Utilising the natural properties of the components, the lubricant rises to the surface of the coolant,

where it can be efficiently removed using a skimmer. Conversely, the denser metal chips and sludge settle at the bottom of

the settling tank and are discharged through a valve. This method presents a promising approach to cleaning the coolant

effectively.

During the environmental review, it was also noted that substantial vertical space exists above the production floor. With the

administrative office on the second floor and part of the production area used for storage, a significant portion of the space

above the CNC machines remains unutilised. This observation sparked the notion of a raised settling tank directly above

the CNC machines. Figure 9 shows the portion of the production floor and the space above the CNC machines. Integrating

a raised settling tank into this space presents an innovative solution to enhance coolant management and optimise the

efficiency of the sedimentation process while minimising the footprint on the production floor.

58