Page 154 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 154

portion, portion by portion. The remaining sterile saline and Figure 5(a) demonstrates the cleaning efficacy of Formulation

eco-enzyme solution were added and mixed uniformly. The 1. While it effectively removed some dirt, residual grime

whole mixture was homogenised for at least 30 minutes. This is to remained. In contrast, Figure 5(b) showcases the superior

ensure the mix is well homogenised and no separation occurs upon performance of Formulation 2. This formulation effectively

resting. The formation of an abrasive detergent with the desired eliminated all dirt, grime, and discolouration, leaving the

texture and cleaning properties was observed. surface clean and restored. Based on these visual results,

Formulation 2 was selected as the final abrasive eco-detergent,

Testing for the effectiveness of abrasive eco detergent with its ingredient composition outlined in Table 4.

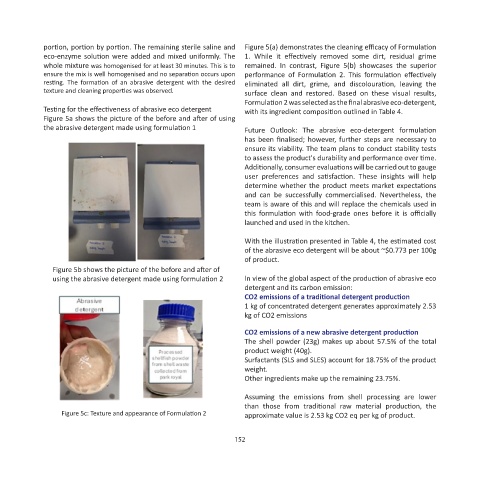

Figure 5a shows the picture of the before and after of using

the abrasive detergent made using formulation 1 Future Outlook: The abrasive eco-detergent formulation

has been finalised; however, further steps are necessary to

ensure its viability. The team plans to conduct stability tests

to assess the product's durability and performance over time.

Additionally, consumer evaluations will be carried out to gauge

user preferences and satisfaction. These insights will help

determine whether the product meets market expectations

and can be successfully commercialised. Nevertheless, the

team is aware of this and will replace the chemicals used in

this formulation with food-grade ones before it is officially

launched and used in the kitchen.

With the illustration presented in Table 4, the estimated cost

of the abrasive eco detergent will be about ~$0.773 per 100g

of product.

Figure 5b shows the picture of the before and after of

using the abrasive detergent made using formulation 2 In view of the global aspect of the production of abrasive eco

detergent and its carbon emission:

CO2 emissions of a traditional detergent production

1 kg of concentrated detergent generates approximately 2.53

kg of CO2 emissions

CO2 emissions of a new abrasive detergent production

The shell powder (23g) makes up about 57.5% of the total

product weight (40g).

Surfactants (SLS and SLES) account for 18.75% of the product

weight.

Other ingredients make up the remaining 23.75%.

Assuming the emissions from shell processing are lower

than those from traditional raw material production, the

Figure 5c: Texture and appearance of Formulation 2 approximate value is 2.53 kg CO2 eq per kg of product.

152