Page 149 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 149

(vi) Total Emission Reduction After the seafood shells waste is collected, washed and

Emission Reduction =Baseline Emissions - (Production disinfected, it is acid-treated with 2.0M Hydrochloric acid and

Emissions + Use Phase Emissions) + Avoided Emissions followed by 5% oxalic acid to remove impurities and increase

= 0.3594 - (0.1106 + 0.2376) + 0.231 its porosity and its property for partial replacement of the

= 0.24216 kg CO2e per 100 ml of used cooking oil cement in making concrete.

Therefore, the estimated total emission reduction is Formulation

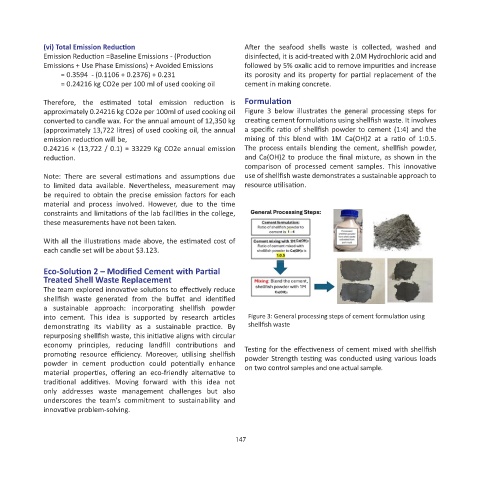

approximately 0.24216 kg CO2e per 100ml of used cooking oil Figure 3 below illustrates the general processing steps for

converted to candle wax. For the annual amount of 12,350 kg creating cement formulations using shellfish waste. It involves

(approximately 13,722 litres) of used cooking oil, the annual a specific ratio of shellfish powder to cement (1:4) and the

emission reduction will be, mixing of this blend with 1M Ca(OH)2 at a ratio of 1:0.5.

0.24216 × (13,722 / 0.1) = 33229 Kg CO2e annual emission The process entails blending the cement, shellfish powder,

reduction. and Ca(OH)2 to produce the final mixture, as shown in the

comparison of processed cement samples. This innovative

Note: There are several estimations and assumptions due use of shellfish waste demonstrates a sustainable approach to

to limited data available. Nevertheless, measurement may resource utilisation.

be required to obtain the precise emission factors for each

material and process involved. However, due to the time

constraints and limitations of the lab facilities in the college,

these measurements have not been taken.

With all the illustrations made above, the estimated cost of

each candle set will be about $3.123.

Eco-Solution 2 – Modified Cement with Partial

Treated Shell Waste Replacement

The team explored innovative solutions to effectively reduce

shellfish waste generated from the buffet and identified

a sustainable approach: incorporating shellfish powder

into cement. This idea is supported by research articles Figure 3: General processing steps of cement formulation using

demonstrating its viability as a sustainable practice. By shellfish waste

repurposing shellfish waste, this initiative aligns with circular

economy principles, reducing landfill contributions and Testing for the effectiveness of cement mixed with shellfish

promoting resource efficiency. Moreover, utilising shellfish powder Strength testing was conducted using various loads

powder in cement production could potentially enhance on two control samples and one actual sample.

material properties, offering an eco-friendly alternative to

traditional additives. Moving forward with this idea not

only addresses waste management challenges but also

underscores the team's commitment to sustainability and

innovative problem-solving.

147