Page 151 - Towards A Sustainable Future , Phase 3 2025, E-Book_Neat

P. 151

Presentation of Data

Table 3: Materials needed for Formulating the Modified Cement and its Estimated Cost (per about 100g)

*Note:

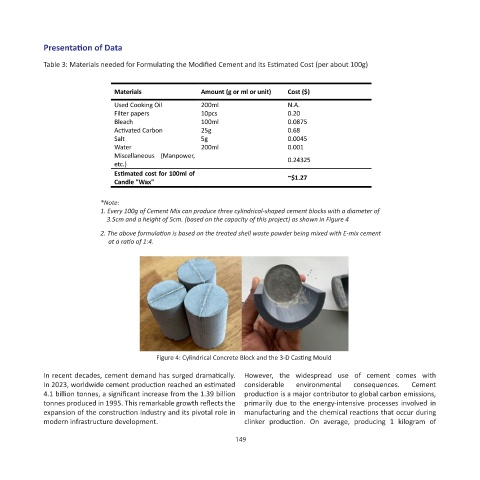

1. Every 100g of Cement Mix can produce three cylindrical-shaped cement blocks with a diameter of

3.5cm and a height of 5cm. (based on the capacity of this project) as shown in Figure 4

2. The above formulation is based on the treated shell waste powder being mixed with E-mix cement

at a ratio of 1:4.

Figure 4: Cylindrical Concrete Block and the 3-D Casting Mould

In recent decades, cement demand has surged dramatically. However, the widespread use of cement comes with

In 2023, worldwide cement production reached an estimated considerable environmental consequences. Cement

4.1 billion tonnes, a significant increase from the 1.39 billion production is a major contributor to global carbon emissions,

tonnes produced in 1995. This remarkable growth reflects the primarily due to the energy-intensive processes involved in

expansion of the construction industry and its pivotal role in manufacturing and the chemical reactions that occur during

modern infrastructure development. clinker production. On average, producing 1 kilogram of

149