Page 19 - SSAB Welding Handbook Edition 2

P. 19

©2009-2019 by SSAB Group of companies (SSAB). All rights reserved. Only digital PDF file. No distribution. No printing allowed!

No part of this handbook may be reproduced in any form or by any means without permission in writing from SSAB.

Welding handbook 4.0 Hydrogen cracks

4.0 Hydrogen cracks

©SSAB

Each type of steel has its own unique characteristics able to form at lower tensile stresses. Different models

regarding its resistance to different kinds of weld exist on how these three parameters interact with each

discontinuities in joints. Hydrogen cracks can form other. However, no exact proven mechanism for the

in different kinds of steels but they are emphasized initiation of hydrogen cracks exists.

in high strength steels including the Hardox and

Strenx grades. The risk for this type of crack in Hydrogen cracks can be surface breaking or exist as

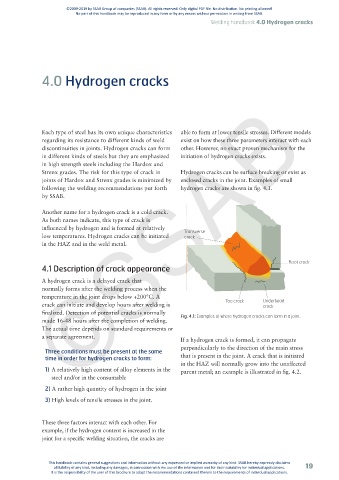

joints of Hardox and Strenx grades is minimized by enclosed cracks in the joint. Examples of small

following the welding recommendations put forth hydrogen cracks are shown in fig. 4.1.

by SSAB.

Another name for a hydrogen crack is a cold crack.

As both names indicate, this type of crack is

influenced by hydrogen and is formed at relatively Transverse

low temperatures. Hydrogen cracks can be initiated crack

in the HAZ and in the weld metal.

Root crack

4.1 Description of crack appearance

A hydrogen crack is a delayed crack that

normally forms after the welding process when the

temperature in the joint drops below +200°C. A Underbead

crack can initiate and develop hours after welding is Toe crack crack

finalized. Detection of potential cracks is normally Fig. 4.1: Examples of where hydrogen cracks can form in a joint.

made 16-48 hours after the completion of welding.

The actual time depends on standard requirements or

a separate agreement.

If a hydrogen crack is formed, it can propagate

perpendicularly to the direction of the main stress

Three conditions must be present at the same

time in order for hydrogen cracks to form: that is present in the joint. A crack that is initiated

in the HAZ will normally grow into the unaffected

1) A relatively high content of alloy elements in the parent metal; an example is illustrated in fig. 4.2.

steel and/or in the consumable

2) A rather high quantity of hydrogen in the joint

3) High levels of tensile stresses in the joint.

These three factors interact with each other. For

example, if the hydrogen content is increased in the

joint for a specific welding situation, the cracks are

This handbook contains general suggestions and information without any expressed or implied warranty of any kind. SSAB hereby expressly disclaims

all liability of any kind, including any damages, in connection with the use of the information and for their suitability for individual applications. 19

It is the responsibility of the user of this brochure to adapt the recommendations contained therein to the requirements of individual applications.