Page 102 - HIL Operatives Training Manual V4 16022024_Neat

P. 102

O P E R A T I V E S T R A I N I N G M A N U A L V E R S I O N 4

21.3 Operating a Counter Balanced Forklift

Operative will be externally trained and competent and have read the RA’s and SSW’s

relevant to the job they are undertaking.

Read and understood the operator’s handbook.

Staff will wear all the necessary PPE provided and instructed.

Follow all safety instructions given and not put themselves at risk.

Ensure that they make eye contact before entering the danger zone of any machine or vehicle

within the working environment.

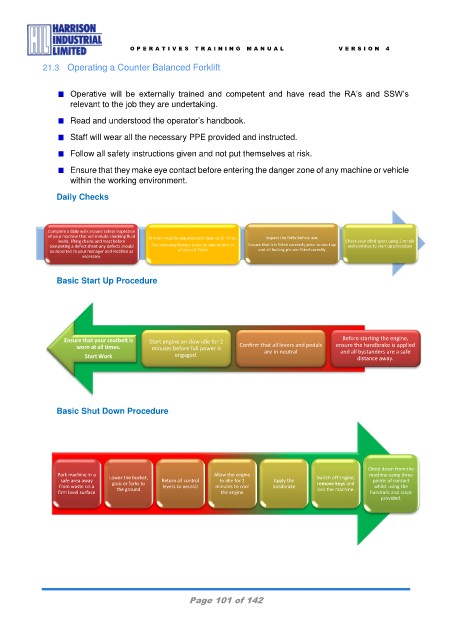

Daily Checks

Complete a daily walk around safety inspection

of your machine that will include checking fluid Mirrors must be adjusted and clean at all times. Inspect the forks before use.

levels, lifting chains and mast before Check your blind spots using 1 m rule

completing a defect sheet-any defects should The reversing bleeper must be operational at Ensure that it is fitted correctly prior to start up and continue to start up procedure

be reported to your manager and rectified as all times if fitted and all locking pin are fitted corectly

necessary.

Basic Start Up Procedure

Ensure that your seatbelt is Start engine on slow idle for 2 Before starting the engine,

worn at all times. minutes before full power is Confirm that all levers and pedals ensure the handbrake is applied

and all bystanders are a safe

are in neutral

Start Work engaged. distance away.

Basic Shut Down Procedure

Climb down from the

Park machine in a Lower the bucket, Allow the engine Switch off Engine, machine using three

safe area away Return all control to idle for 2 Apply the points of contact

from waste on a grab or forks to levers to neutral minutes to cool handbrake remove keys and whilst using the

firm level surface the ground the engine lock the machine. handrails and steps

provided.

Page 101 of 142