Page 99 - Finanancial Management_2022

P. 99

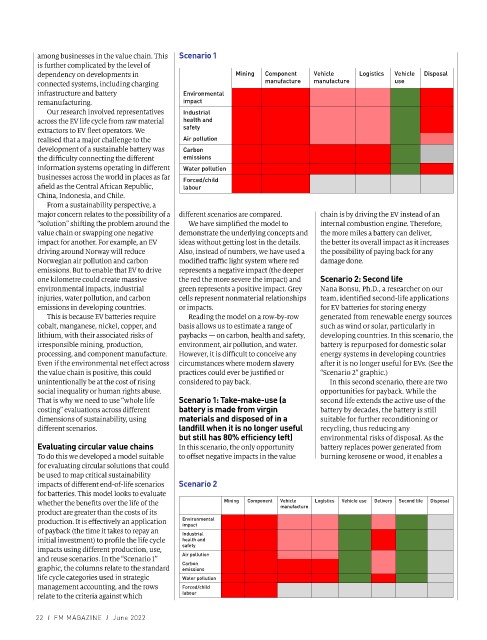

among businesses in the value chain. This Scenario 1

is further complicated by the level of

dependency on developments in Mining Component Vehicle Logistics Vehicle Disposal

connected systems, including charging manufacture manufacture use

infrastructure and battery Environmental

remanufacturing. impact

Our research involved representatives Industrial

across the EV life cycle from raw material health and

extractors to EV fleet operators. We safety

realised that a major challenge to the Air pollution

development of a sustainable battery was Carbon

the difficulty connecting the different emissions

information systems operating in different Water pollution

businesses across the world in places as far Forced/child

afield as the Central African Republic, labour

China, Indonesia, and Chile.

From a sustainability perspective, a

major concern relates to the possibility of a different scenarios are compared. chain is by driving the EV instead of an

“solution” shifting the problem around the We have simplified the model to internal combustion engine. Therefore,

value chain or swapping one negative demonstrate the underlying concepts and the more miles a battery can deliver,

impact for another. For example, an EV ideas without getting lost in the details. the better its overall impact as it increases

driving around Norway will reduce Also, instead of numbers, we have used a the possibility of paying back for any

Norwegian air pollution and carbon modified traffic light system where red damage done.

emissions. But to enable that EV to drive represents a negative impact (the deeper

one kilometre could create massive the red the more severe the impact) and Scenario 2: Second life

environmental impacts, industrial green represents a positive impact. Grey Nana Bonsu, Ph.D., a researcher on our

injuries, water pollution, and carbon cells represent nonmaterial relationships team, identified second-life applications

emissions in developing countries. or impacts. for EV batteries for storing energy

This is because EV batteries require Reading the model on a row-by-row generated from renewable energy sources

cobalt, manganese, nickel, copper, and basis allows us to estimate a range of such as wind or solar, particularly in

lithium, with their associated risks of paybacks — on carbon, health and safety, developing countries. In this scenario, the

irresponsible mining, production, environment, air pollution, and water. battery is repurposed for domestic solar

processing, and component manufacture. However, it is difficult to conceive any energy systems in developing countries

Even if the environmental net effect across circumstances where modern slavery after it is no longer useful for EVs. (See the

the value chain is positive, this could practices could ever be justified or “Scenario 2” graphic.)

unintentionally be at the cost of rising considered to pay back. In this second scenario, there are two

social inequality or human rights abuse. opportunities for payback. While the

That is why we need to use “whole life Scenario 1: Take-make-use (a second life extends the active use of the

costing” evaluations across different battery is made from virgin battery by decades, the battery is still

dimensions of sustainability, using materials and disposed of in a suitable for further reconditioning or

different scenarios. landfill when it is no longer useful recycling, thus reducing any

but still has 80% efficiency left) environmental risks of disposal. As the

Evaluating circular value chains In this scenario, the only opportunity battery replaces power generated from

To do this we developed a model suitable to offset negative impacts in the value burning kerosene or wood, it enables a

for evaluating circular solutions that could

be used to map critical sustainability

impacts of different end-of-life scenarios Scenario 2

for batteries. This model looks to evaluate

whether the benefits over the life of the Mining Component Vehicle Logistics Vehicle use Delivery Second life Disposal

manufacture

product are greater than the costs of its

production. It is effectively an application Environmental

impact

of payback (the time it takes to repay an Industrial

initial investment) to profile the life cycle health and

impacts using different production, use, safety

and reuse scenarios. In the “Scenario 1” Air pollution

graphic, the columns relate to the standard Carbon

emissions

life cycle categories used in strategic Water pollution

management accounting, and the rows Forced/child

relate to the criteria against which labour

22 I FM MAGAZINE I June 2022