Page 28 - Buy Premium Tools ORION Catalogue

P. 28

Drilling tools

Stepped drill bit

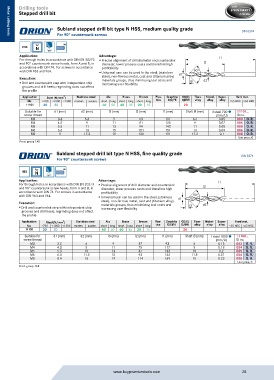

Subland stepped drill bit type N HSS, medium quality grade DIN 8374

For 90° countersunk screws

Metal cutting tools

Metal cutting tools

Typ HA

HSS

N

118°

Application: Advantage:

For through holes in accordance with DIN EN 20273 Precise alignment of drill diameter and countersink l1

and 90° countersunk screw heads, form A and B, in diameter, lower process costs and therefore high l2

accordance with DIN 74. For screws in accordance profitability

with DIN 963 and 964. Universal use: can be used in the steel, (stainless 90°

Execution: steel), non-ferrous metal, cast and (titanium alloy) d1 d2

materials groups, thus minimizing tool costs and

Drill and countersink step with independent chip increasing user flexibility l3

grooves and drill heels; regrinding does not affect

the profile

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11101 30 20 40 50 40 35 20 15 20

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Shaft Ø (mm) f steel 700 11101...

screw thread (mm/U) ID no.

M3 3.4 6.6 9 63 101 6.6 0.05 003 O. R.

M4 4.5 9 11 81 125 9 0.07 004 O. R.

M5 5.5 11 13 94 142 11 0.08 005 O. R.

M6 6.6 13 15 101 151 13 0.09 006 O. R.

M8 9 17.2 19 130 191 17.2 0.1 008 O. R.

Unit price, €

Prod. group 1AR

Subland stepped drill bit type N HSS, fine quality grade DIN 8374

For 90° countersunk screws

Typ HA

HSS N

118°

Application: Advantage: l1

For through holes in accordance with DIN EN 20273 Precise alignment of drill diameter and countersink

and 90° countersunk screw heads, form A and B, in diameter, lower process costs and therefore high l2

accordance with DIN 74. For screws in accordance profitability

with DIN 963 and 964. Universal use: can be used in the steel, (stainless d1 90°

Execution: steel), non-ferrous metal, cast and (titanium alloy) d2

materials groups, thus minimizing tool costs and

Drill and countersink step with independent chip increasing user flexibility l3

grooves and drill heels; regrinding does not affect

the profile

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11100 30 20 40 50 40 35 20 15 20

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Shaft Ø (mm) f steel 1000 11100...

screw thread (mm/U) ID no.

M3 3.2 6 9 57 93 6 0.15 003 O. R.

M4 4.3 8 11 75 117 8 0.18 004 O. R.

M5 5.3 10 13 87 133 10 0.2 005 O. R.

M6 6.4 11.5 15 94 142 11.5 0.21 006 O. R.

M8 8.4 15 19 114 169 15 0.23 008 O. R.

Unit price, €

Prod. group 1AR

www.buypremiumtools.com 28