Page 127 - Buy Premium Tools ATORN Catalogue

P. 127

Reaming tools

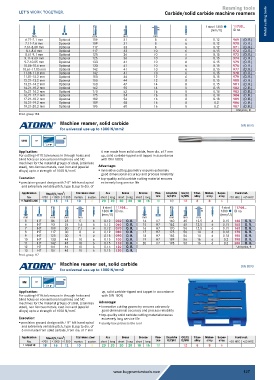

Carbide/solid carbide machine reamers

f steel 1300 11730... Metal cutting tools

h6 (mm/U) ID no.

mm mm mm mm

6.71-7.1 mm Optional 109 31 8 6 0.12 969 (O. R.)

7.11-7.6 mm Optional 109 31 8 6 0.12 970 (O. R.)

7.61-8.09 mm Optional 117 33 8 6 0.12 971 (O. R.)

8.1-8.6 mm Optional 117 33 10 6 0.15 972 (O. R.)

8.61-9.1 mm Optional 125 36 10 6 0.15 973 (O. R.)

9.11-9.69 mm Optional 125 36 10 6 0.15 974 (O. R.)

9.7-10.05 mm Optional 133 41 10 6 0.15 975 (O. R.)

10.06-10.6 mm Optional 133 41 10 6 0.15 976 (O. R.)

10.61-11.05 mm Optional 142 41 10 6 0.15 977 (O. R.)

11.06-11.8 mm Optional 142 41 10 6 0.15 978 (O. R.)

11.81-12.2 mm Optional 150 44 12 6 0.15 979 (O. R.)

12.21-13.2 mm Optional 150 44 12 8 0.15 980 (O. R.)

13.21-14.2 mm Optional 160 47 14 8 0.15 981 (O. R.)

14.21-15.2 mm Optional 162 50 14 8 0.15 982 (O. R.)

15.21-16.2 mm Optional 170 52 16 8 0.18 983 (O. R.)

16.21-17.2 mm Optional 175 54 16 8 0.18 984 (O. R.)

17.21-18.2 mm Optional 182 56 16 8 0.18 985 (O. R.)

18.21-19.2 mm Optional 189 58 16 8 0.2 986 (O. R.)

19.21-20.2 mm Optional 195 60 16 8 0.2 987 (O. R.)

Unit price, €

Prod. group 1BK

Machine reamer, solid carbide DIN 8093

for universal use up to 1300 N/mm2

HA

VHM

7–8°

Application: 6 mm made from solid carbide, from dia. of 7 mm

For cutting H7 fit tolerances in through holes and up, solid carbide-tipped and tappet in accordance

blind holes on conventional machines and NC with DIN 1809)

machines for the material groups of steel, (stainless

steel), non-ferrous metals, cast iron and (special Advantage:

alloys) up to a strength of 1000 N/mm . 2 innovative cutting geometry ensures extremely

good dimensional accuracy and process reliability

Execution: top-quality solid carbide cutting material ensures

precision-ground design with 7-8° left-hand spiral extremely long service life

and extremely variable pitch, type B, (up to dia. of

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11744050-200 18 15 12 10 8 20 20 20 20 18 16 18 10 12 8 8 6

f steel 11744... f steel 11744...

h6 1300 ID no. h6 1300 ID no.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

5 H7 86 23 5 6 0.12 050 O. R. 14 H7 160 45 12.5 6 0.15 140 O. R.

6 H7 93 26 5.6 6 0.12 060 O. R. 15 H7 162 45 12.5 6 0.15 150 O. R.

7 H7 109 30 7.1 4 0.12 070 O. R. 16 H7 170 56 12.5 6 0.15 160 O. R.

8 H7 117 30 8 4 0.12 080 O. R. 17 H7 175 56 14 6 0.18 170 O. R.

9 H7 125 30 9 4 0.15 090 O. R. 18 H7 182 56 14 6 0.18 180 O. R.

10 H7 133 45 10 6 0.15 100 O. R. 19 H7 189 56 16 6 0.2 190 O. R.

11 H7 142 45 10 6 0.15 110 O. R. 20 H7 195 56 16 6 0.2 200 O. R.

12 H7 151 45 10 6 0.15 120 O. R. Unit price, €

13 H7 151 45 10 6 0.15 130 O. R.

Prod. group 117

Machine reamer set, solid carbide DIN 8093

for universal use up to 1300 N/mm2

HA

HM

7–8°

Application: up, solid carbide-tipped and tappet in accordance

For cutting H7 fit tolerances in through holes and with DIN 1809)

blind holes on conventional machines and NC

machines for the material groups of steel, (stainless Advantage:

steel), non-ferrous metals, cast iron and (special innovative cutting geometry ensures extremely

alloys) up to a strength of 1000 N/mm . 2 good dimensional accuracy and process reliability

top-quality solid carbide cutting material ensures

Execution: extremely long service life

precision-ground design with 7-8° left-hand spiral sturdy box protects the tool

and extremely variable pitch, type B, (up to dia. of

6 mm made from solid carbide, from dia. of 7 mm

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11744010 18 15 12 10 8 20 20 20 20 18 16 18 12 8 8 6

www.buypremiumtools.com 127