Page 130 - Buy Premium Tools ATORN Catalogue

P. 130

Reaming tools

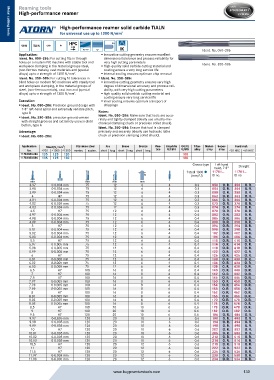

High-performance reamer

High-performance reamer solid carbide TiALN

for universal use up to 1300 N/mm 2

Metal cutting tools

Metal cutting tools

HPC HA

VHM TiAlN 0,001 UNI

7–8° 0° IK Ident. No. 050–286

Application: Innovative cutting geometry ensures excellent

Ident. No. 050–286: For cutting fits in through dimensional tolerance and process reliability for

holes on a modern NC machine with stable tool and very high cutting parameters Ident. No. 350–586

workpiece clamping in the material groups steel, High-quality solid carbide cutting material and

(non-ferrous metals), cast materials and (special coating ensure a very long service life

alloys) up to a strength of 1300 N/mm . 2 Internal cooling ensures optimum chip removal

Ident. No. 350–586: For cutting fit tolerances in Ident. No. 350–586:

blind holes on modern NC machines with steady tool innovative cutting geometry ensures very high

and workpiece clamping, in the material groups of degree of dimensional accuracy and process reli-

steel, (non-ferrous metals), cast iron and (special ability, with very high cutting parameters

alloys) up to a strength of 1300 N/mm . 2 high-quality solid carbide cutting material and

coating ensure very long service life

Execution: inner cooling ensures optimum transport of

Ident. No. 050–286: Precision-ground design with chippings

7-8° left-hand spiral and extremely variable pitch,

type B Notes:

Ident. No. 350–586: precision-ground version Ident. No. 050–286: Make sure that tools are accu-

rately and tightly clamped (ideally use a hydro-me-

with straight grooves and extremely uneven distri- chanical clamping chuck or precision collet chuck).

bution, type A Ident. No. 350–586: Ensure that tool is clamped

Advantage: precisely and securely (ideally use hydraulic lathe

Ident. No. 050–286: chuck or precision clamping collet chuck)!

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11781050-286 135 125 120 100

11781350-586 135 125 120 100

Groove type Left-hand

twist, 7-8° Straight

f steel 1300 11781... 11781...

h6 (mm/U) ID no. ID no.

mm mm mm mm

3.97 0-0.004 mm 75 12 6 4 0.3 050 O. R. 350 O. R.

3.98 0-0.004 mm 75 12 6 4 0.3 054 O. R. 354 O. R.

3.99 0-0.004 mm 75 12 6 4 0.3 058 O. R. 358 O. R.

4 H7 75 12 6 4 0.3 062 O. R. 362 O. R.

4.01 0-0.004 mm 75 12 6 4 0.3 066 O. R. 366 O. R.

4.02 0-0.004 mm 75 12 6 4 0.3 070 O. R. 370 O. R.

4.03 0-0.004 mm 75 12 6 4 0.3 074 O. R. 374 O. R.

4.5 H7 75 12 6 4 0.4 078 O. R. 378 O. R.

4.97 0-0.004 mm 75 12 6 4 0.4 082 O. R. 382 O. R.

4.98 0-0.004 mm 75 12 6 4 0.4 086 O. R. 386 O. R.

4.99 0-0.004 mm 75 12 6 4 0.4 090 O. R. 390 O. R.

5 H7 75 12 6 4 0.4 094 O. R. 394 O. R.

5.01 0-0.004 mm 75 12 6 4 0.4 098 O. R. 398 O. R.

5.02 0-0.004 mm 75 12 6 4 0.4 102 O. R. 402 O. R.

5.03 0-0.004 mm 75 12 6 4 0.4 106 O. R. 406 O. R.

5.5 H7 75 12 6 4 0.4 110 O. R. 410 O. R.

5.97 0-0.005 mm 75 12 6 4 0.4 114 O. R. 414 O. R.

5.98 0-0.005 mm 75 12 6 4 0.4 118 O. R. 418 O. R.

5.99 0-0.005 mm 75 12 6 4 0.4 122 O. R. 422 O. R.

6 H7 75 12 6 4 0.4 126 O. R. 426 O. R.

6.01 0-0.005 mm 75 12 6 4 0.4 130 O. R. 430 O. R.

6.02 0-0.005 mm 75 12 6 4 0.4 134 O. R. 434 O. R.

6.03 0-0.005 mm 75 12 6 4 0.4 138 O. R. 438 O. R.

6.5 H7 100 16 8 6 0.4 140 O. R. 440 O. R.

7 H7 100 16 8 6 0.4 142 O. R. 442 O. R.

7.5 H7 100 16 8 6 0.4 146 O. R. 446 O. R.

7.97 0-0.005 mm 100 16 8 6 0.4 150 O. R. 450 O. R.

7.98 0-0.005 mm 100 16 8 6 0.4 154 O. R. 454 O. R.

7.99 0-0.005 mm 100 16 8 6 0.4 158 O. R. 458 O. R.

8 H7 100 16 8 6 0.4 162 O. R. 462 O. R.

8.01 0-0.005 mm 100 16 8 6 0.4 166 O. R. 466 O. R.

8.02 0-0.005 mm 100 16 8 6 0.4 170 O. R. 470 O. R.

8.03 0-0.005 mm 100 16 8 6 0.4 174 O. R. 474 O. R.

8.5 H7 100 20 10 6 0.6 178 O. R. 478 O. R.

9 H7 100 20 10 6 0.6 182 O. R. 482 O. R.

9.5 H7 120 20 10 6 0.6 186 O. R. 486 O. R.

9.97 0-0.005 mm 120 20 10 6 0.6 190 O. R. 490 O. R.

9.98 0-0.005 mm 120 20 10 6 0.6 194 O. R. 494 O. R.

9.99 0-0.005 mm 120 20 10 6 0.6 198 O. R. 498 O. R.

10 H7 120 20 10 6 0.6 202 O. R. 502 O. R.

10.01 0-0.005 mm 120 20 10 6 0.6 206 O. R. 506 O. R.

10.02 0-0.005 mm 120 20 10 6 0.6 210 O. R. 510 O. R.

10.03 0-0.005 mm 120 20 10 6 0.6 214 O. R. 514 O. R.

10.5 H7 120 20 12 6 0.6 218 O. R. 518 O. R.

11 H7 120 20 12 6 0.6 222 O. R. 522 O. R.

11.5 H7 120 20 12 6 0.6 226 O. R. 526 O. R.

11.97 0-0.005 mm 120 20 12 6 0.6 230 O. R. 530 O. R.

11.98 0-0.005 mm 120 20 12 6 0.6 234 O. R. 534 O. R.

www.buypremiumtools.com 130