Page 132 - Buy Premium Tools ATORN Catalogue

P. 132

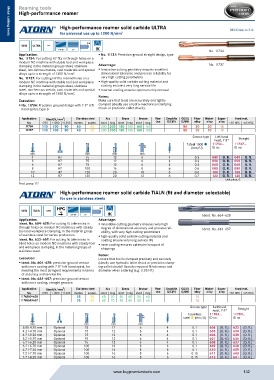

Reaming tools

High-performance reamer

High-performance reamer solid carbide ULTRA DIN Similar to 212

for universal use up to 1300 N/mm 2

Metal cutting tools

Metal cutting tools

HA

VHM ULTRA

7–8° 0° IK No. 11734

Application: No. 11737: Precision-ground straight design, type

No. 11734: For cutting H7 fits in through holes on a A

modern NC machine with stable tool and workpiece No. 11737

clamping in the material groups steel, stainless Advantage:

steel, non-ferrous metals, cast materials and special Innovative cutting geometry ensures excellent

alloys up to a strength of 1300 N/mm . 2 dimensional tolerance and process reliability for

No. 11737: For cutting H7 fits in blind holes on a very high cutting parameters

modern NC machine with stable tool and workpiece High-quality solid carbide cutting material and

clamping in the material groups steel, stainless coating ensure a very long service life

steel, non-ferrous metals, cast materials and special Internal cooling ensures optimum chip removal

alloys up to a strength of 1300 N/mm . 2

Notes:

Execution: Make sure that tools are accurately and tightly

No. 11734: Precision-ground design with 7-8° left- clamped (ideally use a hydro-mechanical clamping

hand spiral, type B chuck or precision collet chuck).

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11734 110 100 90 40 35 200 200 180 180 160 160 80 20 20 18

11737 110 100 90 40 35 200 200 180 180 160 160 80 20 20 18

Groove type Left-hand Straight

twist, 7-8°

f steel 1300 11734... 11737...

h6 (mm/U) ID no. ID no.

mm mm mm mm

4 H7 75 12 6 4 0.3 040 O. R. 040 O. R.

5 H7 75 12 6 4 0.3 050 O. R. 050 O. R.

6 H7 75 12 6 4 0.4 060 O. R. 060 O. R.

8 H7 100 16 8 6 0.6 080 O. R. 080 O. R.

10 H7 120 20 10 6 0.6 100 O. R. 100 O. R.

12 H7 120 20 12 6 0.7 120 O. R. 120 O. R.

Unit price, €

Prod. group 117

High-performance reamer solid carbide TiALN (fit and diameter selectable)

for use in stainless steels

HPC HA

VHM TiAlN 0,00X

VA IK

7–8° 0° Ident. No. 604–628

Application: Advantage:

Ident. No. 604–628: For cutting fit tolerances in innovative cutting geometry ensures very high

through holes on modern NC machines with steady degree of dimensional accuracy and process reli- Ident. No. 633–657

tool and workpiece clamping, in the material group ability, with very high cutting parameters

of stainless steel for series production. high-quality solid carbide cutting material and

Ident. No. 633–657: For cutting fit tolerances in coating ensure very long service life

blind holes on modern NC machines with steady tool inner cooling ensures optimum transport of

and workpiece clamping, in the material groups of chippings

stainless steel.

Notes:

Execution: Ensure that tool is clamped precisely and securely

Ident. No. 604–628: precision-ground version (ideally use hydraulic lathe chuck or precision clamp-

with inner cooling with 7-8° left-hand spiral, for ing collet chuck)! Specify required fit tolerance and

meeting the most stringent requirements in terms diameter when ordering (e.g. 8.05 H7)

of accuracy and service life

Ident. No. 633–657: precision-ground version

with inner cooling, straight grooves

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11783604-628 35 30 60 70 50 60 50 60 15

11783633-657 35 30 60 70 50 60 50 60 15

Groove type Left-hand Straight

twist, 7-8°

f stainless 11783... 11783...

h6 steel (mm/U) ID no. ID no.

mm mm mm mm

3.80-4.20 mm Optional 75 12 6 4 0.1 604 (O. R.) 633 (O. R.)

4.21-4.70 mm Optional 75 12 6 4 0.1 605 (O. R.) 634 (O. R.)

4.71-5.20 mm Optional 75 12 6 4 0.1 606 (O. R.) 635 (O. R.)

5.21-5.70 mm Optional 75 12 6 4 0.1 607 (O. R.) 636 (O. R.)

5.71-6.20 mm Optional 75 12 6 4 0.1 608 (O. R.) 637 (O. R.)

6.21-6.70 mm Optional 100 16 8 6 0.1 609 (O. R.) 638 (O. R.)

6.71-7.20 mm Optional 100 16 8 6 0.1 610 (O. R.) 639 (O. R.)

7.21-7.70 mm Optional 100 16 8 6 0.15 611 (O. R.) 640 (O. R.)

7.71-8.20 mm Optional 100 16 8 6 0.15 612 (O. R.) 641 (O. R.)

www.buypremiumtools.com 132