Page 146 - Buy Premium Tools ATORN Catalogue

P. 146

Tools for threads

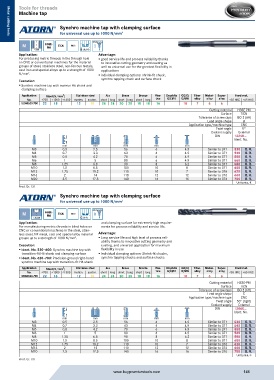

Machine tap

Synchro machine tap with clamping surface

for universal use up to 1000 N/mm 2

Metal cutting tools

Metal cutting tools

CNC/Synchro

M HSSE- TiCN

3xd PM B (3,5-5)

Application: Advantage:

For producing metric threads in the through hole good service life and process reliability thanks

on CNC or conventional machines for the material to innovative cutting geometry and coating as

groups of steel, stainless steel, non-ferrous metals, well as universal use for the greatest flexibility in

cast iron and special alloys up to a strength of 1000 applications

N/mm . 2 individual clamping options: shrink-fit chuck,

Execution: synchro tapping chuck and surface chuck

Synchro machine tap with overrun H6 shank and

clamping surface

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13248620-700 22 15 12 10 24 24 20 20 18 18 16 18 7 6 6

Cutting material HSSE-PM

Surface TiCN

Tolerance of screw taps ISO 2 (6H)

Lead angle shape B

Application type/machine type CNC

Twist angle 0°

Coolant supply External

DIN 13248...

Ident. No.

mm mm mm mm mm

M3 0.5 2.5 56 6 4.9 Similar to 371 530 O. R.

M4 0.7 3.3 63 6 4.9 Similar to 371 540 O. R.

M5 0.8 4.2 70 6 4.9 Similar to 371 550 O. R.

M6 1 5 80 6 4.9 Similar to 371 560 O. R.

M8 1.25 6.8 90 8 6.2 Similar to 371 580 O. R.

M10 1.5 8.5 100 10 8 Similar to 371 600 O. R.

M12 1.75 10.2 110 10 7 Similar to 376 620 O. R.

M16 2 14 110 12 12 Similar to 376 660 O. R.

M20 2.5 17.5 140 16 16 Similar to 376 700 O. R.

Unit price, €

Prod. Gr. 131

Synchro machine tap with clamping surface

for universal use up to 1000 N/mm 2

CNC/Synchro

M HSSE- TiCN

2,5xd PM C (2-3)

Application: and clamping surface for extremely high require-

For manufacturing metric threads in blind holes on ments for process reliability and service life.

CNC or conventional machines in the steel, stain-

less steel, NF metal, cast and special alloy material Advantage:

groups up to a strength of 1000 N/mm . 2 Long service life and high level of process reli-

ability thanks to innovative cutting geometry and

Execution: coating, and universal application for maximum

Ident. No. 530–600: Synchro machine tap with flexibility in use

transition-fit H6 shank and clamping surface Individual clamping options: Shrink-fit chucks,

Ident. No. 620–700: Precision-ground right-hand synchro tapping chucks and surface chucks

synchro machine tap with transition- fit H6 shank

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

13060620-700 22 15 12 10 24 24 20 20 18 18 16 18 7 6 6

Cutting material HSSE-PM

Surface TiCN

Tolerance of screw taps ISO 2 (6H)

Lead angle shape C

Application type/machine type CNC

Twist angle 50° (right)

Coolant supply External

DIN 13060...

Ident. No.

mm mm mm mm mm

M3 0.5 2.5 56 6 4.9 Similar to 371 530 O. R.

M4 0.7 3.3 63 6 4.9 Similar to 371 540 O. R.

M5 0.8 4.2 70 6 4.9 Similar to 371 550 O. R.

M6 1 5 80 6 4.9 Similar to 371 560 O. R.

M8 1.25 6.8 90 8 6.2 Similar to 371 580 O. R.

M10 1.5 8.5 100 10 8 Similar to 371 600 O. R.

M12 1.75 10.2 110 10 7 Similar to 376 620 O. R.

M16 2 14 110 12 12 Similar to 376 660 O. R.

M20 2.5 17.5 140 16 16 Similar to 376 700 O. R.

Unit price, €

Prod. Gr. 131

www.buypremiumtools.com 146