Page 255 - Buy Premium Tools ATORN Catalogue

P. 255

Milling tools

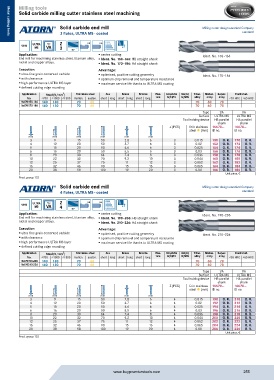

Solid carbide milling cutter stainless steel machining

Solid carbide end mill Milling cutter design standard Company

3 flutes, ULTRA MS - coated standard

Metal cutting tools

Metal cutting tools

ULTRA Typ Z HB HA

VHM VA

MS 3

Application: centre cutting Ident. No. 150–166

End mill for machining stainless steel, titanium alloy, Ident. No. 150–166: HB straight shank

nickel and copper alloys. Ident. No. 170–186: HA straight shank

Execution: Advantage:

ultra-fine grain cemented carbide optimised, positive cutting geometry Ident. No. 170–186

with clearance optimum chip removal and temperature resistance

high-performance ULTRA MS layer maximum service life thanks to ULTRA MS coating

defined cutting edge rounding

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670150-166 140 130 70 60 70 60 70

16670170-186 140 130 70 60 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel HA parallel

shank shank

Z (PCS) fz in stainless 16670... 16670...

steel (mm) ID no. ID no.

mm mm mm mm mm mm

3 9 15 50 2.8 6 3 0.015 150 O. R. 170 O. R.

4 12 20 50 3.7 6 3 0.02 152 O. R. 172 O. R.

5 15 20 50 4.6 6 3 0.025 154 O. R. 174 O. R.

6 16 20 50 5.5 6 3 0.03 156 O. R. 176 O. R.

8 20 30 64 7.4 8 3 0.036 158 O. R. 178 O. R.

10 22 32 70 9.2 10 3 0.044 160 O. R. 180 O. R.

12 25 37 75 11 12 3 0.052 162 O. R. 182 O. R.

16 32 46 90 15 16 3 0.065 164 O. R. 184 O. R.

20 38 58 100 19 20 3 0.08 166 O. R. 186 O. R.

Unit price, €

Prod. group 152

Solid carbide end mill Milling cutter design standard Company

4 flutes, ULTRA MS - coated standard

Typ

VHM ULTRA VA Z HB HA

MS 4

Application: centre cutting Ident. No. 190–206

End mill for machining stainless steel, titanium alloy, Ident. No. 190–206: HB straight shank

nickel and copper alloys. Ident. No. 210–226: HA straight shank

Execution: Advantage:

ultra-fine grain cemented carbide optimised, positive cutting geometry Ident. No. 210–226

with clearance optimum chip removal and temperature resistance

high-performance ULTRA MS layer maximum service life thanks to ULTRA MS coating

defined cutting edge rounding

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16670190-206 140 130 70 60 70 60 70

16670210-226 140 130 70 60 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel HA parallel

shank shank

Z (PCS) fz in stainless 16670... 16670...

steel (mm) ID no. ID no.

mm mm mm mm mm mm

3 9 15 50 2.8 6 4 0.015 190 O. R. 210 O. R.

4 12 20 50 3.7 6 4 0.02 192 O. R. 212 O. R.

5 15 20 50 4.6 6 4 0.025 194 O. R. 214 O. R.

6 16 20 50 5.5 6 4 0.03 196 O. R. 216 O. R.

8 20 30 64 7.4 8 4 0.036 198 O. R. 218 O. R.

10 22 32 70 9.2 10 4 0.044 200 O. R. 220 O. R.

12 25 37 75 11 12 4 0.052 202 O. R. 222 O. R.

16 32 46 90 15 16 4 0.065 204 O. R. 224 O. R.

20 38 58 100 19 20 4 0.08 206 O. R. 226 O. R.

Unit price, €

Prod. group 152

www.buypremiumtools.com 255