Page 259 - Buy Premium Tools ATORN Catalogue

P. 259

Milling tools

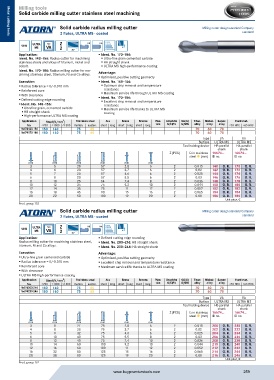

Solid carbide milling cutter stainless steel machining

Solid carbide radius milling cutter Milling cutter design standard Company

2 flutes, ULTRA MS - coated standard

Metal cutting tools

Metal cutting tools

ULTRA Typ Z HB HA

VHM VA

MS 2

Application: Ident. No. 170–186:

Ident. No. 140–156: Radius cutter for machining Ultra-fine grain cemented carbide

stainless steels and alloys of titanium, nickel and HA straight shank

cobalt. ULTRA MS high-performance coating

Ident. No. 170–186: Radius milling cutter for ma- Advantage:

chining stainless steel, titanium, Ni and Co alloys.

Optimised, positive cutting geometry

Execution: Ident. No. 140–156:

Radius tolerance = 0/-0.010 mm Optimum chip removal and temperature

Reinforced core resistance

Maximum service life through ULTRA MS coating

With clearance Ident. No. 170–186:

Defined cutting edge rounding Excellent chip removal and temperature

Ident. No. 140–156: resistance

Ultrafine grain, cemented carbide Maximum service life thanks to ULTRA MS

HB straight shank coating

High-performance ULTRA MS coating

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16674140-156 150 140 75 65 70 60 70

16674170-186 150 140 75 65 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel HA parallel

shank shank

Z (PCS) fz in stainless 16674... 16674...

steel (mm) ID no. ID no.

mm mm mm mm mm mm

3 5 20 57 2.8 6 2 0.015 140 O. R. 170 O. R.

4 6 20 57 3.7 6 2 0.02 142 O. R. 172 O. R.

5 7 20 57 4.6 6 2 0.025 144 O. R. 174 O. R.

6 8 20 57 5.5 6 2 0.03 146 O. R. 176 O. R.

8 10 25 64 7.4 8 2 0.036 148 O. R. 178 O. R.

10 12 35 75 9.2 10 2 0.044 150 O. R. 180 O. R.

12 14 35 75 11 12 2 0.052 152 O. R. 182 O. R.

16 18 45 90 15 16 2 0.065 154 O. R. 184 O. R.

20 22 50 100 19 20 2 0.08 156 O. R. 186 O. R.

Unit price, €

Prod. group 152

Solid carbide radius milling cutter Milling cutter design standard Company

2 flutes, ULTRA MS - coated standard

VHM ULTRA Typ Z HB HA

MS VA 2

Application: Defined cutting edge rounding

Radius milling cutter for machining stainless steel, Ident. No. 200–216: HB straight shank

titanium, Ni and Co alloys. Ident. No. 230–246: HA straight shank

Execution: Advantage:

Ultra-fine grain cemented carbide Optimised, positive cutting geometry

Radius tolerance = 0/-0.010 mm Excellent chip removal and temperature resistance

Reinforced core Maximum service life thanks to ULTRA MS coating

With clearance

ULTRA MS high-performance coating

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16674200-216 150 140 75 65 70 60 70

16674230-246 150 140 75 65 70 60 70

Type VA VA

Surface ULTRA MS ULTRA MS

Tool holding device HB parallel HA parallel

shank shank

Z (PCS) fz in stainless 16674... 16674...

steel (mm) ID no. ID no.

mm mm mm mm mm mm

3 5 21 75 2.8 6 2 0.015 200 O. R. 230 O. R.

4 8 28 75 3.7 6 2 0.02 202 O. R. 232 O. R.

5 9 32 75 4.6 6 2 0.025 204 O. R. 234 O. R.

6 10 40 75 5.5 8 2 0.03 206 O. R. 236 O. R.

8 12 40 75 7.4 10 2 0.036 208 O. R. 238 O. R.

10 14 60 100 9.2 10 2 0.044 210 O. R. 240 O. R.

12 16 60 100 11 12 2 0.052 212 O. R. 242 O. R.

16 32 80 125 15 16 2 0.065 214 O. R. 244 O. R.

20 38 80 125 19 20 2 0.08 216 O. R. 246 O. R.

Unit price, €

Prod. group 152

www.buypremiumtools.com 259