Page 261 - Buy Premium Tools ATORN Catalogue

P. 261

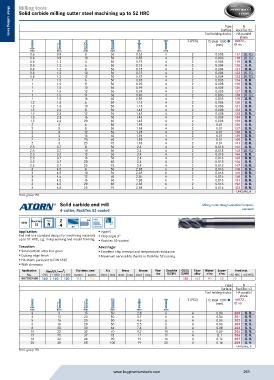

Milling tools

Solid carbide milling cutter steel machining up to 52 HRC

Type N

Surface RockTec 52

Tool holding device HA parallel

shank

Metal cutting tools

Metal cutting tools

Z (PCS) fz steel 1300 16972...

(mm) ID no.

mm mm mm mm mm mm

0.6 0.9 8 50 0.55 4 2 0.003 117 (O. R.)

0.6 0.9 10 50 0.55 4 2 0.003 118 (O. R.)

0.8 1.2 4 50 0.75 4 2 0.004 119 O. R.

0.8 1.2 6 50 0.75 4 2 0.004 120 O. R.

0.8 1.2 8 50 0.75 4 2 0.004 121 O. R.

0.8 1.2 10 50 0.75 4 2 0.004 122 (O. R.)

0.8 1.2 12 50 0.75 4 2 0.004 123 (O. R.)

1 1.5 6 50 0.95 4 2 0.005 124 O. R.

1 1.5 8 50 0.95 4 2 0.005 125 O. R.

1 1.5 10 50 0.95 4 2 0.005 126 O. R.

1 1.5 12 50 0.95 4 2 0.005 127 O. R.

1 1.5 14 50 0.95 4 2 0.005 128 (O. R.)

1 1.5 16 60 0.95 4 2 0.005 129 O. R.

1.2 1.8 6 50 1.15 4 2 0.006 130 O. R.

1.2 1.8 10 50 1.15 4 2 0.006 131 O. R.

1.5 2.3 8 50 1.45 4 2 0.008 132 O. R.

1.5 2.3 12 50 1.45 4 2 0.008 133 O. R.

1.5 2.3 16 50 1.45 4 2 0.008 134 O. R.

1.5 2.3 20 60 1.45 4 2 0.008 135 O. R.

2 3 6 50 1.95 4 2 0.01 136 O. R.

2 3 8 50 1.95 4 2 0.01 137 O. R.

2 3 12 50 1.95 4 2 0.01 138 O. R.

2 3 16 50 1.95 4 2 0.01 139 O. R.

2 3 20 60 1.95 4 2 0.01 140 O. R.

2 3 25 75 1.95 4 2 0.01 141 O. R.

2.5 3.7 8 50 2.4 4 2 0.013 142 O. R.

2.5 3.7 10 50 2.4 4 2 0.013 143 (O. R.)

2.5 3.7 12 50 2.4 4 2 0.013 144 O. R.

2.5 3.7 16 50 2.4 4 2 0.013 145 O. R.

2.5 3.7 20 60 2.4 4 2 0.013 146 O. R.

2.5 3.7 25 75 2.4 4 2 0.013 147 O. R.

3 4.5 8 50 2.85 6 2 0.016 148 O. R.

3 4.5 10 50 2.85 6 2 0.016 149 O. R.

3 4.5 12 50 2.85 6 2 0.016 150 O. R.

3 4.5 16 60 2.85 6 2 0.016 151 O. R.

3 4.5 20 60 2.85 6 2 0.016 152 O. R.

3 4.5 25 75 2.85 6 2 0.016 153 O. R.

Unit price, €

Prod. group 152

Solid carbide end mill Milling cutter design standard Company

4-cutter, RockTec 52-coated standard

VHM RockTec Typ Z HA

52 N 4

Application: Type N

End mill in a standard design for machining materials Chip angle 3°

up to 52 HRC, e.g. in dip working and mould forming. RockTec 52-coated

Execution: Advantage:

Solid carbide ultra-fine grain Excellent chip removal and temperature resistance

Cutting edge finish Maximum service life thanks to RockTec 52 coating

HA shank pursuant to DIN 6535

With clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16972200-208 160 150 120 115 100 130 100 90 80 70

Type N

Surface RockTec 52

Tool holding device HA parallel

shank

Z (PCS) fz steel 1300 16972...

(mm) ID no.

mm mm mm mm mm mm

3 9 15 50 2.8 6 4 0.03 200 O. R.

4 12 20 50 3.7 6 4 0.04 201 O. R.

5 15 20 50 4.6 6 4 0.05 202 O. R.

6 16 20 50 5.5 6 4 0.06 203 O. R.

8 20 30 64 7.4 8 4 0.08 204 O. R.

10 22 32 70 9.2 10 4 0.09 205 O. R.

12 25 37 75 11 12 4 0.1 206 O. R.

16 32 46 90 15 16 4 0.12 207 O. R.

20 38 58 100 19 20 4 0.16 208 O. R.

Unit price, €

Prod. group 152

www.buypremiumtools.com 261