Page 63 - Buy Premium Tools ATORN Catalogue

P. 63

Drilling tools

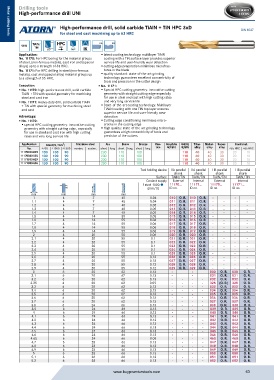

High-performance drill UNI

High-performance drill, solid carbide TiAlN + TiN HPC 3xD DIN 6537

for steel and cast machining up to 63 HRC

Metal cutting tools

Metal cutting tools

TiAlN/ HPC HA HB

VHM

TiN UNI IK

3xD 140°

Application: latest coating technology: multilayer TiAlN

No. 11170: For HPC boring for the material groups coating with a TiN surface layer provides superior

of steel, (non-ferrous metals), cast iron and (special service life and user-friendly wear detection

alloys) up to a strength of 63 HRC. cutting edge preparation minimises microfrac-

No. 11171: For HPC drilling in steel (non-ferrous tures in the blade

metals), cast and (special alloy) material groups up quality standard: state-of-the-art grinding

to a strength of 55 HRC. technology guarantees excellent concentricity of

tools and precision in the cutter design

Execution: No. 11171:

No. 11170: high-performance drill, solid carbide Special HPC cutting geometry: innovative cutting

TiAlN + TiN with special geometry for machining geometry with straight cutting edge especially

steel and cast iron for use in steel and cast with high cutting rates

No. 11171: Heavy-duty drill, solid carbide TiAlN and very long service life

+ TiN with special geometry for machining steel State-of-the-art coating technology: Multilayer

and cast TIALN coating with one TIN top layer ensures

superior service life and user-friendly wear

Advantage: detection

No. 11170: Cutting edge conditioning minimises micro-

special HPC cutting geometry: innovative cutting cracks in the cutting edge

geometry with straight cutting edge, especially High quality: state-of-the-art grinding technology

for use in steel and cast iron with high cutting guarantees a high concentricity of tools and

rates and very long service life precision of the cutters

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11170010-029 130 100 90 230 110 100 110 40 40 30 20 10

11170030-555 130 100 90 230 110 100 110 40 40 30 20 10

11171010-029 130 100 90 230 110 100 110 40 40 30 20 10

11171030-555 130 100 90 230 110 100 110 40 40 30 20 10

Tool holding device HA parallel HA parallel HB parallel HB parallel

shank shank shank shank

Surface TiAlN/TiN TiAlN/TiN TiAlN/TiN TiAlN/TiN

Coolant supply External Internal External Internal

f steel 1000 11170... 11171... 11170... 11171...

h6 (mm/U) ID no. ID no. ID no. ID no.

mm mm mm mm

1 4 7 45 0.04 010 O. R. 010 O. R. - - - -

1.1 4 7 45 0.04 011 O. R. 011 O. R. - - - -

1.2 4 7 45 0.05 012 O. R. 012 O. R. - - - -

1.3 4 7 45 0.05 013 O. R. 013 O. R. - - - -

1.4 4 7 45 0.05 014 O. R. 014 O. R. - - - -

1.5 4 14 55 0.05 015 O. R. 015 O. R. - - - -

1.6 4 14 55 0.06 016 O. R. 016 O. R. - - - -

1.7 4 14 55 0.06 017 O. R. 017 O. R. - - - -

1.8 4 14 55 0.06 018 O. R. 018 O. R. - - - -

1.9 4 14 55 0.06 019 O. R. 019 O. R. - - - -

2 4 20 55 0.06 020 O. R. 020 O. R. - - - -

2.1 4 20 55 0.1 021 O. R. 021 O. R. - - - -

2.2 4 20 55 0.1 022 O. R. 022 O. R. - - - -

2.3 4 20 55 0.1 023 O. R. 023 O. R. - - - -

2.4 4 20 55 0.1 024 O. R. 024 O. R. - - - -

2.5 4 20 55 0.1 025 O. R. 025 O. R. - - - -

2.6 4 20 55 0.12 026 O. R. 026 O. R. - - - -

2.7 4 20 55 0.12 027 O. R. 027 O. R. - - - -

2.8 4 20 55 0.12 028 O. R. 028 O. R. - - - -

2.9 4 20 55 0.12 029 O. R. 029 O. R. - - - -

3 6 20 62 0.13 - - - - 030 O. R. 030 O. R.

3.1 6 20 62 0.13 - - - - 031 O. R. 031 O. R.

3.2 6 20 62 0.13 - - - - 032 O. R. 032 O. R.

3.25 6 20 62 0.09 - - - - 325 (O. R.) 325 O. R.

3.3 6 20 62 0.13 - - - - 033 O. R. 033 O. R.

3.4 6 20 62 0.13 - - - - 034 O. R. 034 O. R.

3.5 6 20 62 0.13 - - - - 035 O. R. 035 O. R.

3.6 6 20 62 0.13 - - - - 036 O. R. 036 O. R.

3.7 6 20 62 0.13 - - - - 037 O. R. 037 O. R.

3.8 6 24 66 0.13 - - - - 038 O. R. 038 O. R.

3.9 6 24 66 0.13 - - - - 039 O. R. 039 O. R.

4 6 24 66 0.13 - - - - 040 O. R. 040 O. R.

4.1 6 24 66 0.13 - - - - 041 O. R. 041 O. R.

4.2 6 24 66 0.13 - - - - 042 O. R. 042 O. R.

4.3 6 24 66 0.13 - - - - 043 O. R. 043 O. R.

4.4 6 24 66 0.13 - - - - 044 O. R. 044 O. R.

4.5 6 24 66 0.13 - - - - 045 O. R. 045 O. R.

4.6 6 24 66 0.13 - - - - 046 O. R. 046 O. R.

4.65 6 24 66 0.09 - - - - 465 O. R. 465 O. R.

4.7 6 28 66 0.13 - - - - 047 O. R. 047 O. R.

4.8 6 28 66 0.13 - - - - 048 O. R. 048 O. R.

4.9 6 28 66 0.13 - - - - 049 O. R. 049 O. R.

5 6 28 66 0.13 - - - - 050 O. R. 050 O. R.

5.1 6 28 66 0.13 - - - - 051 O. R. 051 O. R.

5.2 6 28 66 0.13 - - - - 052 O. R. 052 O. R.

www.buypremiumtools.com 63