Page 7 - The HandPrint_May_Safety_Electronic

P. 7

HAZARD REPORTING PROGRAM

In addition to addressing at-risk behaviors, it is also important to proactively address at risk conditions.

A drop box was installed for plant team members to report hazardous conditions. In order to incentivize

team members to report hazards, a monthly prize raffle is held for all submissions. Since May 2017,

over 40 items have been reported and repaired. This proactive approach has clearly created a safer

work environment.

Building a culture focused on safety is not achieved overnight. However, it is clear that efforts to be

proactive are already having an impact. In 2017, the GOJO Manufacturing Center, Lippman Campus

reported a total of 7 safety incidents. This is a huge reduction from the 13 incidents reported in 2016.

If you SEE a HAZARDOUS

CONDITION, REPORT it!

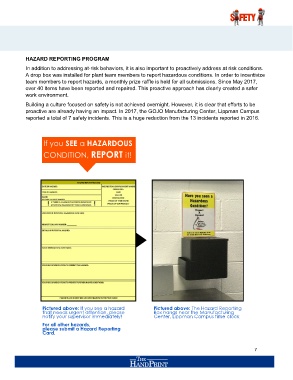

Pictured above: If you see a hazard Pictured above: The Hazard Reporting

that needs urgent attention, please Box hangs near the Manufacturing

notify your supervisor immediately! Center, Lippman Campus time clock

For all other hazards,

please submit a Hazard Reporting

Card.

7