Page 92 - UL_Report On_Part 1

P. 92

83 IITGN-UL/Façade 84 IITGN-UL/Façade

Ventilation condition

Initial ventilation was provided through full opening of the ground

floor (entrance) fire door of dimensions 1m x 2.2m at ground floor.

No initial ventilation was provided at first and second floor levels.

Shattering of glass panels during the fire progress increased the

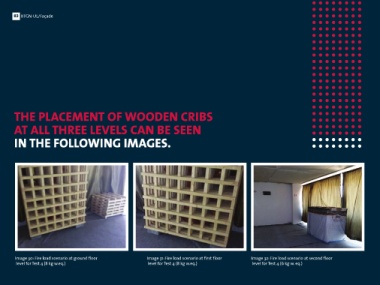

ventilation conditions, as shown in Figure 36.wood members of size

38mm x 38mm x 750mm arranged in alternate layers at right

angles (18 layers of 8) was placed outside test compartment close

to the ventilation provided in the façade assembly in order to allow

THE PLACEMENT OF WOODEN CRIBS easy propagation of fire from crib to the façade assembly and then

within the compartment.

Stainless steel plate of 33cm diameter filled up to 1.15 cm with

AT ALL THREE LEVELS CAN BE SEEN gasoline placed beneath the crib was used as an ignition source.

Density of gasoline is 719.7 kg/m3 while its calorific value of is 45.8

IN THE FOLLOWING IMAGES. MJ/kg. Using these values, the fire load used as ignition source was Figure 36: Variation of ventilation factor w.r.t time at all floor levels for Test 4

32.4 MJ

Ignition Source

Stainless steel dish of 33 cm diameter filled up to 1.15 cm with gasoline placed beneath

the wooden crib at ground floor was used as an ignition source.

Density of Gasoline = 719.7 kg/m3and calorific value of Gasoline is 45.8 MJ/kg. Using

these values, fire load used as ignition source = 32.4 MJ

Image 30: Fire load scenario at ground floor Image 31: Fire load scenario at first floor Image 32: Fire load scenario at second floor

level for Test 4 (8 kg w.eq.) level for Test 4 (8 kg w.eq.) level for Test 4 (6 kg w. eq.)