Page 13 - Induction Manual With Plants

P. 13

Indorama Nigeria

The Polyethylene Plant (PE)

Designed Capacity: 300 KTA

Technology: Nova Chemicals, Canada

The Polyethylene Plant (PE) uses Sclairtech Technology licensed by DuPont

(Novachem) of Canada. The Swing-Plant was built by Kobe Steel of Japan and is capable

of producing both High and Linear Low-Density categories of Poly Ethylene. Ethylene is

the raw material for PE plant and it comes from Olefin Plant.

High density and Low-density particles grow in reactor at polymerization step, where

monomer, ethylene and solvent, cyclohexene is combined with co monomers, Butene-1

and catalysts and co catalyst. Unreacted catalyst is removed from the polymer and then it

process through the extrusion to get the PE pellets. Then these polymer pellets are

transferred to warehouse for bagging. The unique feature of this process is the ability to

swing from High to Linear Low and vice versa in short spans of time.

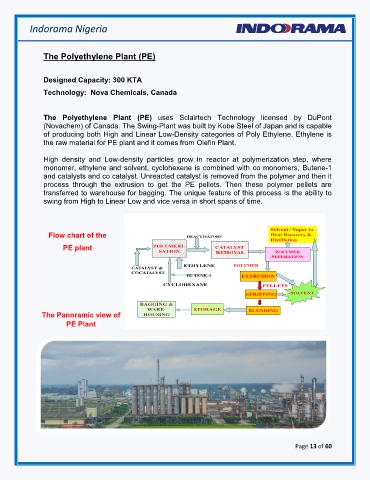

Solvent / Vapor to

Flow chart of the DEACTIVATORS Heat Recovery &

Distillation

PE plant POLYMERI- CATALYST

SATION REMOVAL POLYMER

SEPERATION

ETHYLENE POLYMER

CATALYST &

COCATALYST

BUTENE-1 EXTRUSION

CYCLOHEXANE PELLETS

STRIPPING SOLVENT

BAGGING &

WARE- STORAGE BLENDING

The Panoramic view of HOUSING

PE Plant

Page 13 of 60