Page 12 - Induction Manual With Plants

P. 12

Indorama Nigeria

The Olefins Plant

Designed Capacity: 300KTA

Technology: Kellogg Brown & Root (KBR)

The Olefins Plant uses the technology licensed by Kellogg Brown & Root (KBR) of USA.

The plant has six SCORE furnaces of millisecond technology, of which five are usually

operated and the sixth is used for de-coking or as standby.

The feed stock Natural Gas Liquid (NGL) is fed into the fractionators where C5+

hydrocarbons are recovered at the bottom and C2 to C4 fractions are fed to the cracker

furnaces along with recycle gases – ethane, propane and butane. Ethylene and

Propylene are the main products of Olefins plant, while pentane, hydrogen and fuel gas

are the by-products.

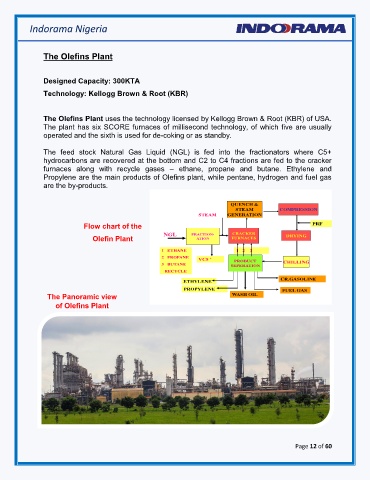

QUENCH &

STEAM COMPRESSION

GENERATION

STEAM

Flow chart of the PRF

NGL FRACTION- CRACKER DRYING

Olefin Plant ATION FURNACES

1 ETHANE 1 2 3

2 PROPANE VC5 +

PRODUCT

3 BUTANE SEPERATION CHILLING

RECYCLE

ETHYLENE CR.GASOLINE

PROPYLENE FUEL GAS

The Panoramic view WASH OIL

of Olefins Plant

Page 12 of 60