Page 38 - Moldex3d training Manual

P. 38

Below this are the material’s Freeze Temperature and Eject Temperature, which will be used in the

interpretation of the results. Commented [CD9]: We should explain where these come

from and specifically what they are used for.

The Freeze Temperature is the transition temperature of the material from a molten state to a solidified

state and can be easily tested for.

The Eject Temperature is typically 20-30 degrees below the Freeze Temperature and will define when the

part should be ejected from the mold. This value is definable by the user, but the default value is provided

as a recommendation based on the type of polymer.

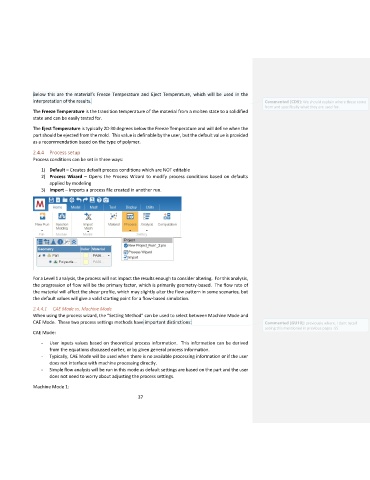

2.4.4 Process setup

Process conditions can be set in three ways:

1) Default – Creates default process conditions which are NOT editable

2) Process Wizard – Opens the Process Wizard to modify process conditions based on defaults

applied by modeling

3) Import – Imports a process file created in another run.

For a Level 1 analysis, the process will not impact the results enough to consider altering. For this analysis,

the progression of flow will be the primary factor, which is primarily geometry-based. The flow rate of

the material will affect the shear profile, which may slightly alter the flow pattern in some scenarios, but

the default values will give a valid starting point for a flow-based simulation.

2.4.4.1 CAE Mode vs. Machine Mode

When using the process wizard, the “Setting Method” can be used to select between Machine Mode and

CAE Mode. These two process settings methods have important distinctions: Commented [GU10]: previously where, I dont recall

seeing this mentioned in previous pages -SS

CAE Mode:

- User inputs values based on theoretical process information. This information can be derived

from the equations discussed earlier, or by given general process information.

- Typically, CAE Mode will be used when there is no available processing information or if the user

does not interface with machine processing directly.

- Simple flow analysis will be run in this mode as default settings are based on the part and the user

does not need to worry about adjusting the process settings.

Machine Mode 1:

37