Page 18 - Tunnel Support Components

P. 18

TUNNEL SUPPORT COMPONENTS

Installation

10HP Hydraulic Unit

Fluid Cap

When doing maintenance, be sure fluid cap is securely tightened so not to allow debris to get inside of

the tank.

CAUTION

If the reservoir needs to be refilled, be sure to use the same type used during initial startup.

NEVER mix the two fluid types together!

Fluid Level Sensor

The sensor requires 24VDC to be supplied. The Fluid Level Sensor

can be adjusted to detect various, desired oil levels. This can be very

beneficial in a case where the oil is slightly low and you need to

keep running while more is being sought. In this case you can loosen

the knurled locking ring and slide the wand deeper into the tank. Knurled

This will prevent the system from shutting down. If this becomes Locking

necessary, pay close attention to the pre-set depth of the wand. Ring

Be sure to raise it back to its original position once the oil is returned

to the proper level.

Note: DO NOT OPERATE WITH LOW OIL LEVELS FOR EXTENDED PERIODS.

Main Electrical Feed

The system requires 208/230/460, 3-phase power supplied from the MCC panel.

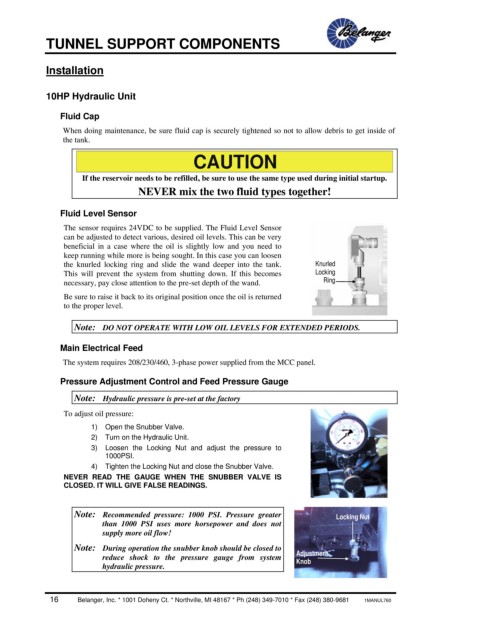

Pressure Adjustment Control and Feed Pressure Gauge

Note: Hydraulic pressure is pre-set at the factory

To adjust oil pressure:

1) Open the Snubber Valve.

2) Turn on the Hydraulic Unit.

3) Loosen the Locking Nut and adjust the pressure to

1000PSI.

4) Tighten the Locking Nut and close the Snubber Valve.

NEVER READ THE GAUGE WHEN THE SNUBBER VALVE IS

CLOSED. IT WILL GIVE FALSE READINGS.

Note: Recommended pressure: 1000 PSI. Pressure greater Locking Nut

than 1000 PSI uses more horsepower and does not

supply more oil flow!

Note: During operation the snubber knob should be closed to

reduce shock to the pressure gauge from system Adjustment

Knob

hydraulic pressure.

16 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL760