Page 18 - MixStir® Chemical Delivery System

P. 18

MIXSTIR® CHEMICAL DELIVERY SYSTEM

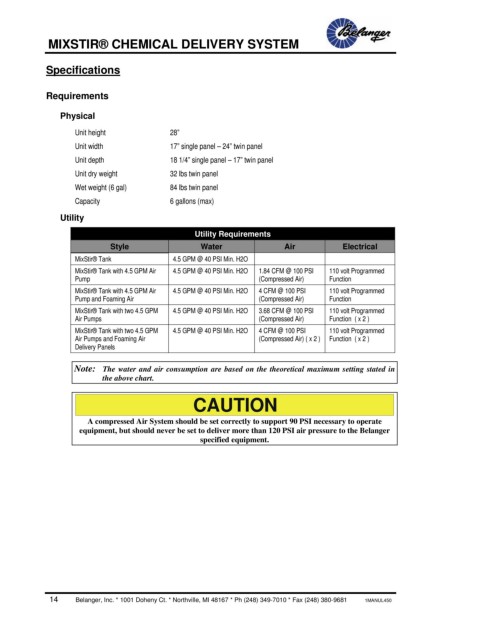

Specifications

Requirements

Physical

Unit height 28”

Unit width 17” single panel – 24” twin panel

Unit depth 18 1/4” single panel – 17” twin panel

Unit dry weight 32 lbs twin panel

Wet weight (6 gal) 84 lbs twin panel

Capacity 6 gallons (max)

Utility

Utility Requirements

Style Water Air Electrical

MixStir® Tank 4.5 GPM @ 40 PSI Min. H2O

MixStir® Tank with 4.5 GPM Air 4.5 GPM @ 40 PSI Min. H2O 1.84 CFM @ 100 PSI 110 volt Programmed

Pump (Compressed Air) Function

MixStir® Tank with 4.5 GPM Air 4.5 GPM @ 40 PSI Min. H2O 4 CFM @ 100 PSI 110 volt Programmed

Pump and Foaming Air (Compressed Air) Function

MixStir® Tank with two 4.5 GPM 4.5 GPM @ 40 PSI Min. H2O 3.68 CFM @ 100 PSI 110 volt Programmed

Air Pumps (Compressed Air) Function ( x 2 )

MixStir® Tank with two 4.5 GPM 4.5 GPM @ 40 PSI Min. H2O 4 CFM @ 100 PSI 110 volt Programmed

Air Pumps and Foaming Air (Compressed Air) ( x 2 ) Function ( x 2 )

Delivery Panels

Note: The water and air consumption are based on the theoretical maximum setting stated in

the above chart.

CAUTION

A compressed Air System should be set correctly to support 90 PSI necessary to operate

equipment, but should never be set to deliver more than 120 PSI air pressure to the Belanger

specified equipment.

14 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 1MANUL450