Page 23 - MixStir® Chemical Delivery System

P. 23

MIXSTIR® CHEMICAL DELIVERY SYSTEM

Utility Connections

Field Supplied Items

1/4" Poly-Flow Tube Water Supply with field supplied Ball Valve

3/8” Poly-Flow Tube Air Line feeds to the 2 secondary tanks From the 3-way divider on the primary panel

1/2” Poly-Flow Tube Main Air Drop with field supplied ball valve 110V Program output from customer’s controller

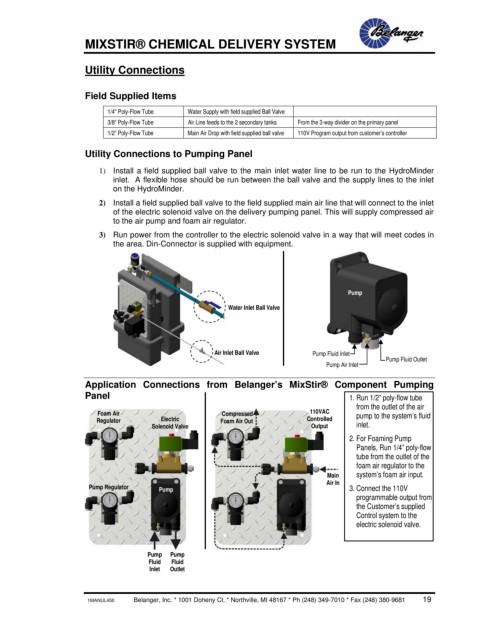

Utility Connections to Pumping Panel

1) Install a field supplied ball valve to the main inlet water line to be run to the HydroMinder

inlet. A flexible hose should be run between the ball valve and the supply lines to the inlet

on the HydroMinder.

2) Install a field supplied ball valve to the field supplied main air line that will connect to the inlet

of the electric solenoid valve on the delivery pumping panel. This will supply compressed air

to the air pump and foam air regulator.

3) Run power from the controller to the electric solenoid valve in a way that will meet codes in

the area. Din-Connector is supplied with equipment.

Pump

Water Inlet Ball Valve

Air Inlet Ball Valve Pump Fluid Inlet

Pump Air Inlet Pump Fluid Outlet

Application Connections from Belanger’s MixStir® Component Pumping

Panel 1. Run 1/2” poly-flow tube

from the outlet of the air

Foam Air Compressed 110VAC pump to the system’s fluid

Regulator Electric Foam Air Out Controlled

Solenoid Valve Output inlet.

2. For Foaming Pump

Panels, Run 1/4” poly-flow

tube from the outlet of the

foam air regulator to the

Main system’s foam air input.

Air In

Pump Regulator Pump 3. Connect the 110V

programmable output from

the Customer’s supplied

Control system to the

electric solenoid valve.

Pump Pump

Fluid Fluid

Inlet Outlet

1MANUL450 Belanger, Inc. * 1001 Doheny Ct. * Northville, MI 48167 * Ph (248) 349-7010 * Fax (248) 380-9681 19